Which Vehicles Mandate Electric Transaxles

Introduction

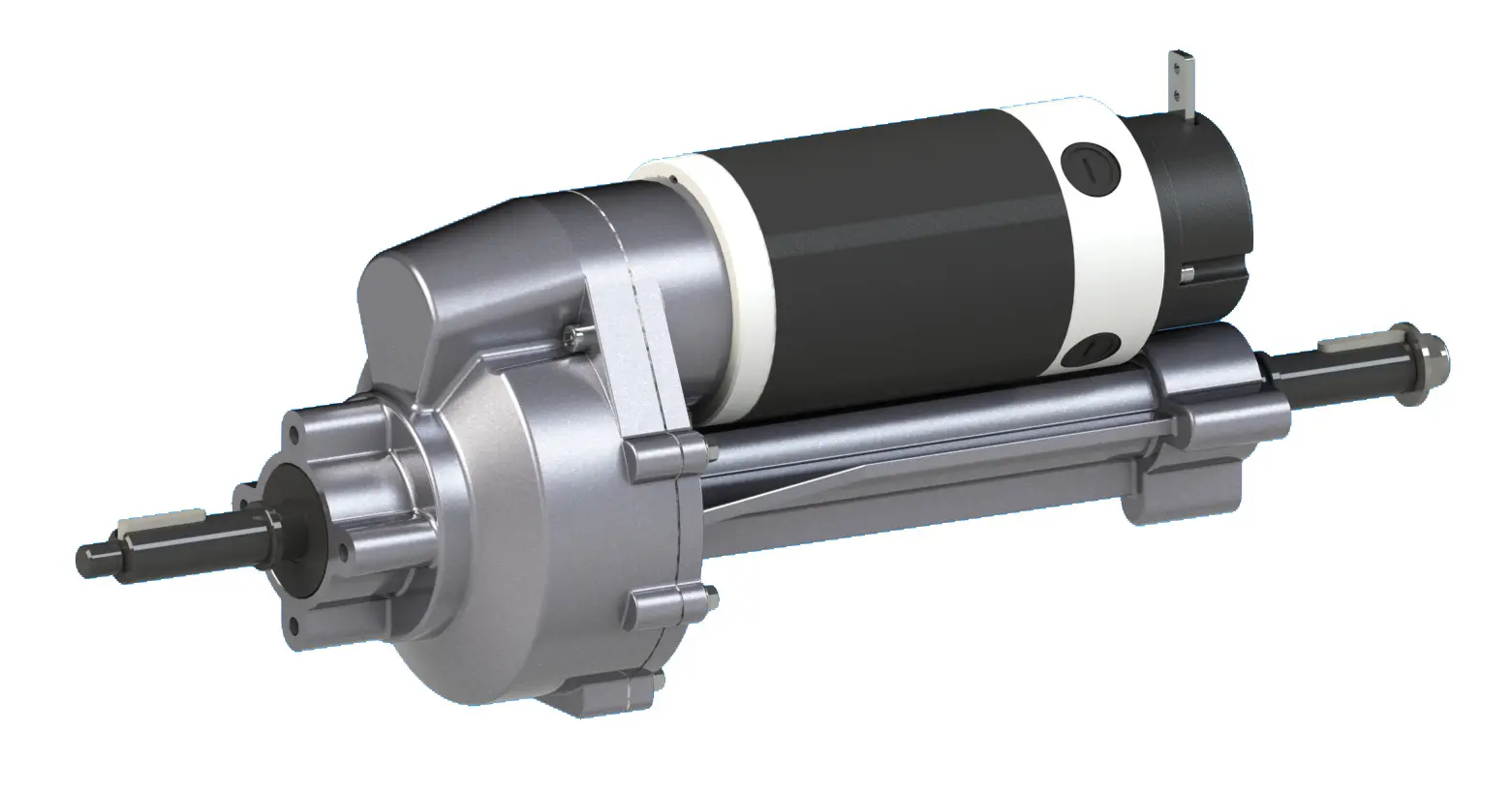

In the rapidly evolving landscape of the automotive and transportation industries, the transition from traditional internal combustion engines to electric powertrains is gaining momentum. One critical component at the heart of this transformation is the electric transaxle. This blog post will delve into the various types of vehicles that mandate the use of electric transaxles, exploring the reasons behind their necessity and the benefits they offer. From heavy-duty logistics trucks to nimble urban delivery vehicles, and from rugged mining trucks to cutting-edge autonomous vehicles, the electric transaxle is proving to be a game-changer across a wide range of applications.

Logistics Heavy Trucks

Logistics heavy trucks are among the most significant adopters of electric transaxles, driven by stringent regulations and the need for efficiency and sustainability. According to Document No. 7 of the Ministry of Industry and Information Technology in China, logistics heavy trucks with a total mass of 12 tons or more must be equipped with electric drive axles. This mandate is not just about reducing emissions; it is also about enhancing performance and reducing operational costs.

Performance and Efficiency

Electric transaxles offer several advantages for heavy trucks. For instance, Foton Daimler’s newly released EST-EL2 features a three-in-one electric drive axle that reduces transmission losses to below 5%. This not only saves electricity but also delivers a peak torque of 18,000 N·m, making it capable of handling heavy loads on challenging terrains like the Qinghai-Tibet routes. Additionally, electric transaxles come with extended maintenance intervals, reducing downtime and maintenance costs.

Regulatory Compliance

Regulations are pushing the industry towards electric transaxles. In China, diesel vehicles that have not been modified to meet the new standards before 2025 will face hefty fines, up to 820,000 yuan. This has led to a rapid adoption of electric transaxle technology, with manufacturers and fleet operators realizing that the transition to electric is not just beneficial but necessary for survival in the market.

Urban Delivery Trucks

Urban delivery trucks are another category of vehicles that are increasingly mandating electric transaxles. The shift is driven by the need to reduce emissions in urban areas and improve fuel efficiency.

Technical Specifications

According to the 2024 Urban Delivery Vehicle Technical Specifications, all 4.5-ton intracity delivery trucks must install electric drive axles by the end of the year, with older vehicles phased out by June 2025. This move is expected to significantly reduce emissions and improve air quality in urban centers.

Cost and Maintenance

The cost benefits of electric transaxles are substantial. For a 200km/day 4.2m box truck, diesel costs 116 yuan/100km, whereas an electric transaxle reduces this to 27 yuan. Moreover, electric transaxles come with advanced failure early warning systems that predict bearing issues 48 hours in advance, reducing the risk of sudden breakdowns and associated costs.

Airport Tug Trucks

Airport tug trucks are essential for moving aircraft on the ground. These vehicles operate in challenging conditions, often in extreme temperatures and with high reliability requirements.

Performance in Extreme Conditions

Electric transaxles offer significant advantages in such scenarios. Unlike diesel engines, which struggle to start in cold temperatures, electric transaxles deliver stable torque within 0.3 seconds. This reliability is crucial for airport operations, where any delay can have significant financial implications.

Environmental Impact

The environmental benefits are also substantial. For instance, Shenzhen Airport Group’s retrofit case in 2023 showed that replacing diesel systems with electric transaxles reduced monthly ground emissions from 87 tons to 21 tons. This not only helps in meeting environmental regulations but also enhances the sustainability profile of airports.

New Energy Buses

New energy buses are another sector where electric transaxles are becoming mandatory. These buses operate in demanding conditions, requiring high torque and reliability.

Technical Challenges

One of the main challenges faced by new energy buses is the need for high instant torque. According to the 2023 National New Energy Vehicle Innovation Project report, 70% of new energy bus electric transaxles fail within the first maintenance cycle due to insufficient torque. This has led to the development of more robust and efficient electric transaxles.

Maintenance and Reliability

Maintenance is another critical aspect. For example, Suzhou King Long’s new liquid cooling system lowers peak temperatures by 14℃, although it adds 83kg to the vehicle’s weight. Despite the added weight, the benefits in terms of reduced maintenance and increased reliability make electric transaxles a compelling choice for new energy buses.

Special Engineering Vehicles

Special engineering vehicles, such as mining trucks and port vehicles, also mandate the use of electric transaxles due to their ability to handle extreme conditions and heavy loads.

High Torque and Efficiency

Electric transaxles offer high torque and efficiency, which are essential for these vehicles. For instance, XCMG’s XDE440 mining trucks, upgraded with dual liquid-cooled motors, deliver 820kN·m peak torque and reduce fuel consumption by 42%. This not only improves performance but also reduces operational costs.

Extreme Conditions

Electric transaxles are designed to operate in extreme conditions, such as the -55℃ temperatures encountered in Antarctic vehicles. Self-heating electric transaxles can operate at -60℃, ensuring that these vehicles remain functional even in the harshest environments.

Autonomous Vehicles

Autonomous vehicles represent the cutting edge of automotive technology, and electric transaxles are a fundamental component of these vehicles.

Precision and Reliability

Autonomous vehicles require precise and reliable power delivery, which electric transaxles provide. For example, Bosch’s Gen2 electric transaxle achieves an 8ms response time, compared to the 120-150ms delay of hydraulic steering. This rapid response time is crucial for the safe and efficient operation of autonomous vehicles.

Safety and Redundancy

Safety is a paramount concern in autonomous vehicles, and electric transaxles offer several advantages in this regard. For instance, SAE J3016’s latest revision mandates dual-redundant electric drives for L4+ autonomy, ensuring that these vehicles can operate safely even in the event of a failure. Electric transaxles also support advanced safety features such as regenerative braking and dynamic torque distribution.

Post time: Aug-15-2025