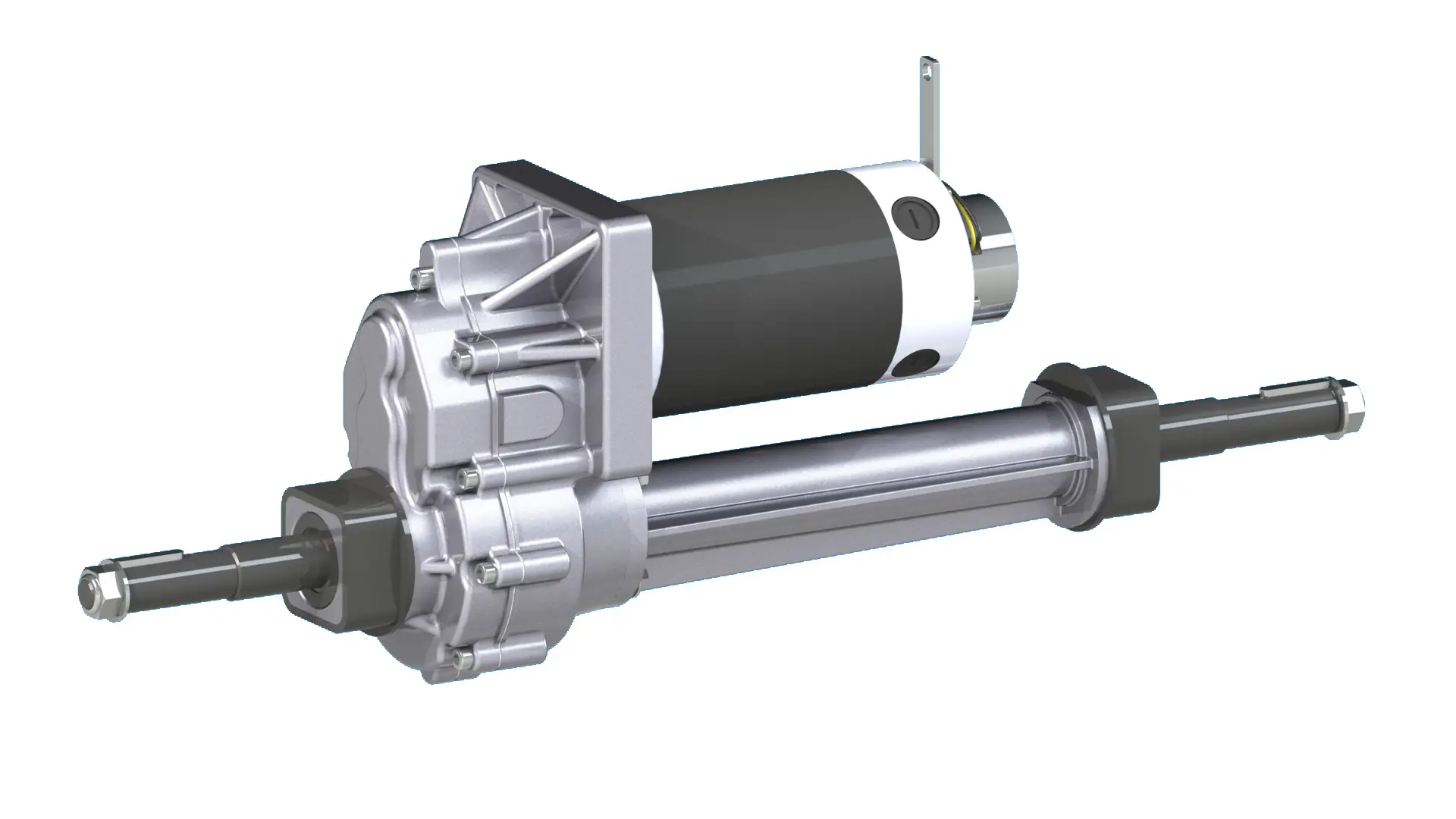

A transaxle is a critical component of modern vehicles, integrating the transmission and differential to convert the engine’s rotational power into usable torque that propels the vehicle forward. It is an essential part of front-wheel drive or all-wheel drive systems. Below are some warning signs of a failing electric transaxle:

Performance Issues

Gear Slipping: If the vehicle cannot maintain a particular gear or shifts to neutral automatically while driving, it may indicate gear slipping caused by worn clutch plates, malfunctioning solenoid valves, low fluid levels, or other issues. Gear slipping can compromise driving safety, as the power transmission between the engine and wheels becomes unstable. In severe cases, it may even lead to complete transmission failure.

Difficult or Delayed Shifting: When shifting gears, if there is a noticeable delay or difficulty, such as a pause after shifting into drive or reverse gears, or if it feels jerky and hard to shift into the correct gear, this could be caused by worn internal seals, low fluid levels, clogged filters, faulty shift solenoids, etc. These issues can disrupt the smooth operation of the electric transaxle and may worsen over time, affecting the vehicle’s drivability.

Vehicle Acceleration Problems: If the vehicle exhibits reduced acceleration performance or feels sluggish when accelerating, as if the engine is not transmitting power effectively to the wheels, it may be due to malfunctioning components within the electric transaxle, such as faulty gears or bearings. This prevents the transaxle from properly increasing torque, impacting the vehicle’s acceleration and overall performance.

Abnormal Sounds

Whining, Grinding, or Clanging Noises: These sounds may indicate issues such as worn bearings, damaged gears, or insufficient lubrication within the electric transaxle. For example, worn bearings may produce a continuous whining sound, while damaged gears could generate grinding or clanging noises. Such abnormal sounds are signs of potential internal component failure and should be addressed promptly to prevent further damage to the transaxle.

Rattling in Fifth Gear: In some cases, a vehicle may rattle at low RPMs in fifth gear due to faulty transaxle fluid. Typically, using high-quality synthetic gear oil can resolve this issue. However, if the rattling persists, it may indicate other problems within the electric transaxle, such as misaligned components or worn parts.

Fluid-Related Issues

Fluid Leaks: Fluid leaks are one of the most common problems faced by electric transaxles. They are often caused by damaged seals, gaskets, or cracks in the housing. Transmission fluid serves as a lubricant and coolant for the transaxle. Leaking fluid can lead to insufficient lubrication and cooling of internal components, accelerating wear and potentially causing overheating. If left unresolved, fluid leaks can severely damage the electric transaxle and other drivetrain components.

Fluid Level Low or Color Abnormalities: Regularly check the fluid level and quality in the electric transaxle. If the fluid level is low, or if the fluid appears dark, burnt, or contaminated, it may indicate internal damage or impending failure. Dark, charred, or contaminated fluid suggests that the transaxle has overheated or that internal components have worn, causing debris to mix with the fluid. In such cases, the fluid should be promptly drained and replaced, and a professional inspection of the transaxle should be conducted.

Warning Lights and Error Codes

When the vehicle’s dashboard displays a transaxle warning light or related error codes, it often indicates potential issues with the electric transaxle or its associated components. For instance, problems such as overheating, mechanical failures within the transaxle (e.g., worn gears, bearings, or seals), electrical/sensor malfunctions, shift interlock failures, valve body issues, or torque converter problems may trigger the warning light. Using an OBD-II scanner to retrieve error codes can help narrow down the issue. For example, a “torque converter clutch circuit” code might explain shuddering at highway speeds, while a “shift solenoid B stuck off” code could correlate with gear slipping issues in third gear.

Overheating Issues

Electric transaxle overheating can result from heavy loads, towing, extreme driving conditions, or faulty cooling systems. Overheating can cause the fluid to break down, losing its lubricating properties and damaging internal components. This may lead to the transaxle warning light illuminating and, in severe cases, result in complete transaxle failure. To prevent overheating, avoid overloading the vehicle, refrain from prolonged towing under high temperatures, and ensure the transaxle cooling system functions properly.

Vibration and Shaking

Excessive vibration or shaking while driving may indicate problems with the electric transaxle. Causes could include misaligned components, damaged CV joints, or worn transmission mounts. Ignoring this symptom may lead to further damage to surrounding parts, such as axles and propshafts. If vibration or shaking occurs, it is advisable to have the vehicle inspected at a professional repair shop as soon as possible to identify and resolve the underlying issue.

Burning Smell

A strong burning odor from the vehicle could signal a malfunctioning electric transaxle. Common causes include low fluid levels, poor fluid quality, or a malfunctioning cooling system. Overheated transmission fluid can lose its lubricating properties, increasing friction and potentially causing damage. A burning smell might also indicate that fluid has leaked onto hot engine parts. This odor signals severe stress on the transmission and requires urgent attention. Regular maintenance, such as checking and replacing transmission fluid, can help prevent such issues.

Other Issues

No Drive or Reduced Drive Speed: Some electric transaxle systems may display error codes like “No Drive” or “Reduced Drive Speed.” For example, in Hydro-Gear’s Integrated Electric LT Drive System, codes such as 02A11 to 02A19 may indicate internal diagnostic malfunctions. If the issue persists after cycling the key, the traction controller may need replacement. Code 02A22, which signals “Reduced Drive Speed” or “No Drive,” could point to a malfunctioning brake during the startup sequence, requiring replacement of the fail-safe brake.

Limp Mode Activation: When an electric transaxle encounters serious issues, some vehicles may enter “limp mode” as a failsafe measure. The transmission locks into third gear to limit further damage. In this mode, the vehicle feels sluggish from a stop and refuses to shift gears. Limp mode often accompanies a warning light and significantly alters the driving experience, indicating that the vehicle requires immediate attention.

Below are some troubleshooting tips and preventive measures for electric transaxle issues:

Regular Maintenance

Adhering to the manufacturer’s recommended maintenance schedule is crucial for keeping the electric transaxle in optimal condition. Regular fluid changes, filter replacements, and inspections can help identify and resolve minor issues before they escalate into major problems.

Monitor Warning Signs

Stay vigilant and watch for any changes in vehicle behavior. If unusual noises, leaks, or performance issues arise, consult a qualified mechanic for immediate diagnosis and resolution.

Fluid Checks

Regularly monitor the fluid level and quality in the electric transaxle. Dark, charred, or contaminated fluid may indicate internal damage or impending failure. Maintaining proper fluid levels and quality can extend the lifespan of the transaxle.

Professional Assistance

If you lack the technical expertise or tools needed to diagnose or repair electric transaxle problems, seek help from a professional mechanic or authorized service center. These professionals possess the knowledge and experience required to accurately identify and resolve transaxle-related issues.

Avoid Overloading and Extreme Driving Conditions

Avoid overloading the vehicle or towing heavy loads in extreme conditions, as these can place excessive stress on the electric transaxle, accelerating wear and increasing the risk of overheating. If the vehicle must be used under such conditions, ensure the transaxle is well-maintained and equipped with an efficient cooling system.

Address Issues Promptly

When warning signs of a failing electric transaxle appear, do not ignore them. Timely repairs can prevent minor issues from worsening and avoid costly overhauls or replacements. Regular maintenance and early intervention are key to extending the lifespan of the electric transaxle and ensuring the vehicle’s performance and safety.

In summary, the electric transaxle is a vital component of modern vehicles. Understanding its warning signs and taking appropriate measures can help prevent unexpected failures and ensure smooth vehicle operation. Vehicle owners should be mindful of the aforementioned warning signs and perform regular maintenance to keep the electric transaxle in good condition. If issues arise, seek professional assistance promptly to diagnose and resolve the problems. Below is a detailed list of warning signs for electric transaxle failure

Post time: May-26-2025