What are the potential energy efficiency improvements with electric transaxles?

In the rapidly evolving landscape of automotive technology, electric transaxles have emerged as a crucial component in the quest for enhanced energy efficiency in vehicles. For businesses venturing into the electric transaxle market and targeting international wholesale buyers, understanding and articulating these energy efficiency potentials is vital. This blog post delves into the various aspects of how electric transaxles can significantly improve energy efficiency, providing valuable insights for your independent site.

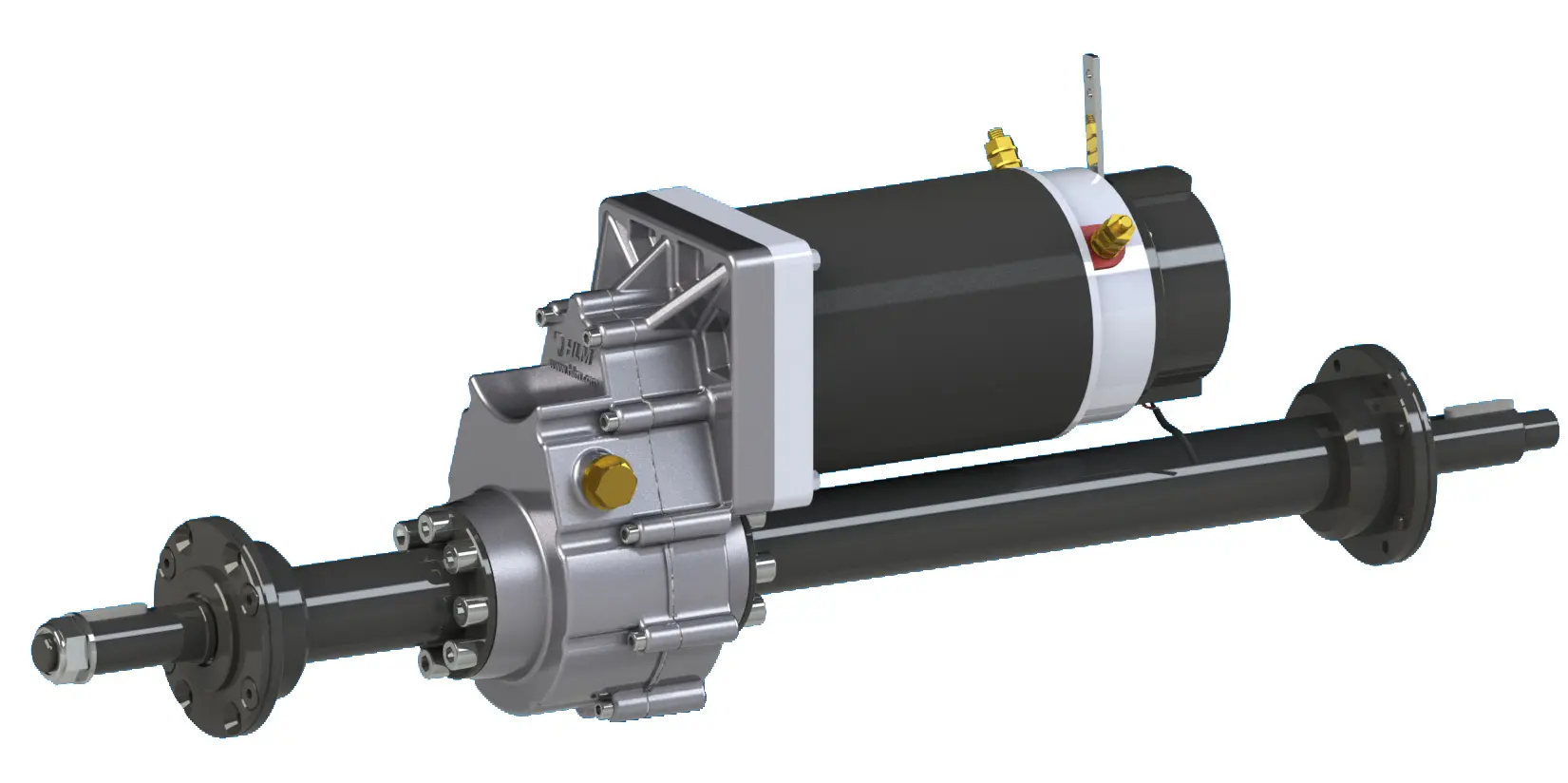

The basics of electric transaxles

An electric transaxle is a compact unit that integrates the electric motor, transmission, and differential into a single assembly. Unlike traditional internal combustion engine (ICE) drivetrains, it eliminates the need for many complex components, resulting in a more streamlined and efficient powertrain. This integrated design is fundamental to the energy efficiency advantages it offers.

Key mechanisms for energy efficiency improvements

Direct energy transfer

Electric transaxles enable direct energy transfer from the electric motor to the wheels. This minimizes energy losses that typically occur during the transfer between separate components in traditional mechanical systems. By reducing these energy losses, electric transaxles can convert over 90% of the energy from the battery into vehicle, movement far surpassing the efficiency of traditional ICEs.

Regenerative braking

Regenerative braking is a standout feature of electric transaxles. During deceleration or braking, the electric motor acts as a generator, capturing the kinetic energy that would otherwise be lost and converting it back into electrical energy. This energy is then stored in the vehicle’s battery for later use. Studies have shown that regenerative braking can recover up to 70% of the energy that would otherwise be lost, significantly enhancing overall energy efficiency and extending the vehicle’s range.

Optimized gear ratios

Electric transaxles can be designed with optimized gear ratios that ensure the motor operates in its most efficient range. Unlike ICEs, which have a narrow range of speeds and loads for optimal efficiency, electric motors can maintain high efficiency across a broader spectrum of operating conditions. By carefully selecting gear ratios, electric transaxles allow the motor to operate at its peak efficiency more frequently, thereby improving energy utilization.

Efficient power management

Electric transaxles are highly adept at managing power output based on driving conditions. They can adjust torque distribution in real-time, ensuring optimal power use and minimizing energy waste. This efficiency translates to improved battery life and extended vehicle range. For example, certain electric transaxle models have demonstrated efficiency improvements of up to 15%.

Weight reduction

Electric transaxles are generally lighter than their mechanical counterparts. The reduction in size and weight of the powertrain components means the vehicle requires less power to move, further enhancing energy efficiency and performance. On average, electric transaxles are 30% lighter than traditional drivetrain systems, which not only improves range but also contributes to better handling and stability.

Integration with vehicle systems

The integration of electric transaxles with other vehicle systems, such as advanced driving aids and vehicle dynamics control systems, can further optimize energy efficiency. For instance, predictive energy management systems can anticipate driving conditions and adjust the energy usage of the electric transaxle accordingly, ensuring the most efficient operation possible.

Comparison with traditional drivetrains

When compared to traditional ICE drivetrains, the energy efficiency advantages of electric transaxles are evident. ICEs face challenges such as thermodynamic limitations, energy losses during combustion, and the complexity of multiple moving parts, all of which contribute to their lower efficiency, typically ranging from 20% to 30%. In contrast, electric transaxles achieve energy utilization efficiencies well above 90%, making them a more efficient and sustainable choice for modern vehicles.

Future developments and innovations

As technology continues to advance, the energy efficiency of electric transaxles is expected to improve further. Ongoing research and development in areas such as motor design, power electronics, and advanced materials will contribute to even higher efficiency levels. For example, the exploration of new motor topologies, such as axial-flux motors, and the use of wide-bandgap semiconductors in power electronics promise significant efficiency gains. Additionally, the integration of electric transaxles with emerging technologies like autonomous driving and vehicle-to-grid systems will open up new avenues. for energy optimization.

Conclusion

In conclusion, electric transaxles offer substantial potential for energy efficiency improvements in vehicles. Their direct energy transfer, regenerative braking capabilities, optimized gear ratios, efficient power management, weight reduction, and integration with vehicle systems all contribute to enhanced energy utilization and reduced energy consumption. For businesses in the electric transaxle market, emphasizing these energy efficiency advantages can be a powerful strategy to attract international wholesale buyers and gain a competitive edge in the industry

Post time: Jun-30-2025