What are the key challenges for electric transaxles in winter?

Introduction

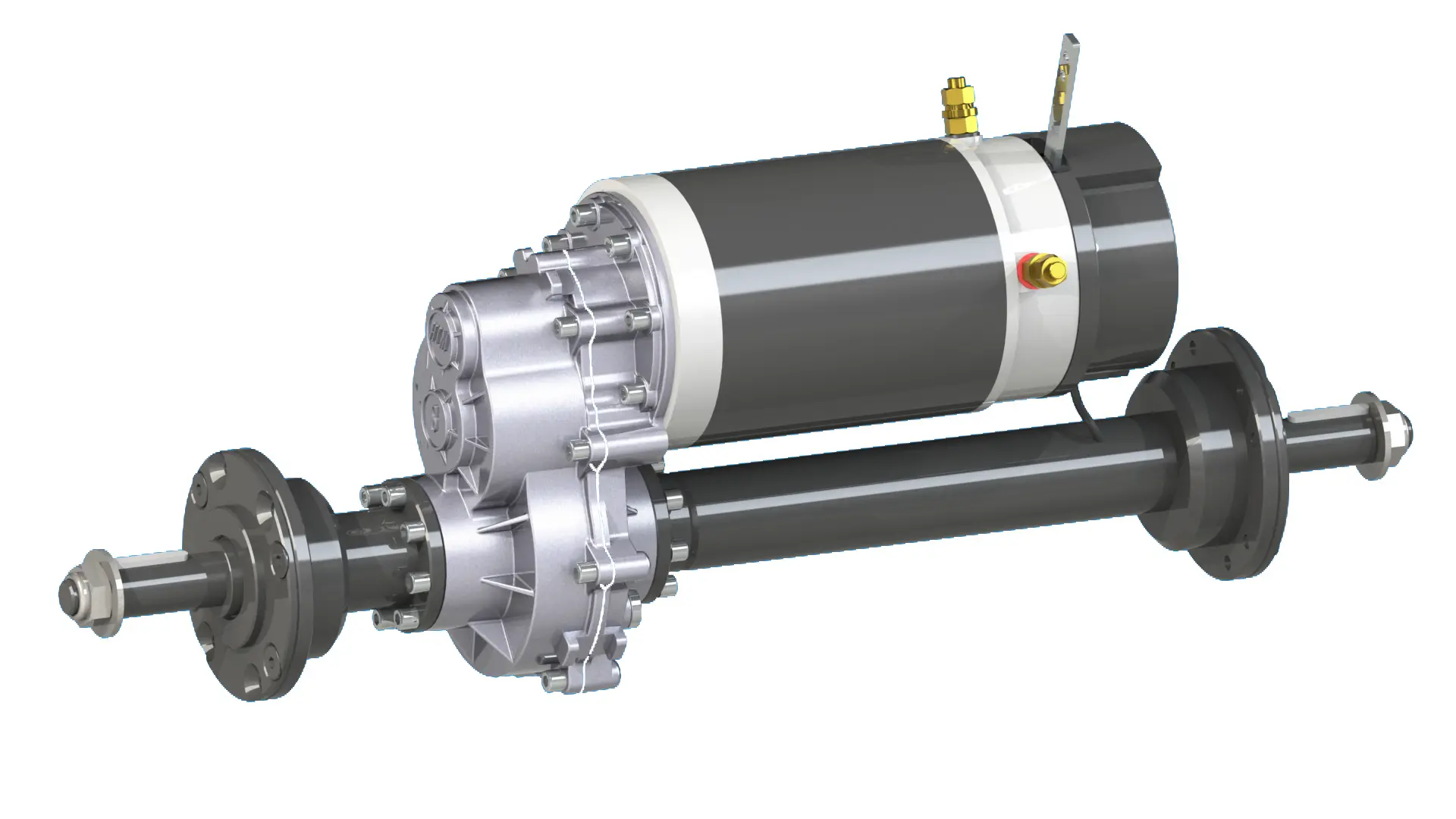

With the continuous development of electric vehicles (EVs), electric transaxles, as one of their core components, are playing an increasingly important role. However, in winter, electric transaxles face several unique challenges that can affect the performance, efficiency, and lifespan of EVs. This blog will explore these key challenges in detail.

The impact of low temperatures on battery performance

Reduced battery efficiency and capacity:In winter, the cold weather can slow down the chemical reactions within lithium-ion batteries, leading to a temporary reduction in their efficiency and capacity. This may result in a shorter driving range for EVs. According to research by AAA, when the temperature drops to 20°F and the HVAC system is used to heat the car’s interior, the average driving range can decrease by 41%.

Extended charging times:Low temperatures also slow down the battery’s ability to accept a charge, significantly increasing charging times. This can be particularly inconvenient for drivers who need to charge their vehicles in cold garages or at outdoor charging stations.

Changes in lubricant viscosity

Increased viscosity and poor lubrication:When the temperature drops below zero degrees, the viscosity of the transmission fluid in electric transaxles can become too high, making it difficult to properly lubricate the internal components. This can lead to increased wear and tear on parts such as gears and bearings, potentially causing noise, vibration, and even transmission failures.

Selection of lubricants:Choosing a high-quality synthetic lubricant with suitable viscosity and low-temperature performance is crucial. Synthetic lubricants generally have better low-temperature fluidity and high-temperature stability, ensuring proper lubrication and protection for the electric transaxle in winter.

Thermal management system limitations

Difficulty in maintaining optimal operating temperature:Electric transaxles rely on thermal management systems to maintain an optimal operating temperature. In winter, the cold ambient temperatures make it harder for the thermal management system to quickly raise and stabilize the temperature of the transaxle components. This can result in the transaxle operating at suboptimal temperatures for extended periods, affecting its performance and efficiency.

Increased burden on the thermal management system:To counteract the cold weather, the thermal management system needs to work harder, which places a greater strain on the system itself. This can lead to issues such as coolant degradation, leaks, or blockages in the cooling system, potentially affecting the normal operation of the electric transaxle.

Increased risk of condensation and corrosion

Formation of condensation:When the temperature difference between the electric transaxle components and the ambient air is significant, moisture in the air can condense on the surfaces of the components, forming water droplets. This condensation can mix with residual lubricants or other substances, creating a corrosive environment.

Corrosion of components:Over time, the condensed water can cause corrosion of metal components such as gears, bearings, and housings. Corrosion weakens the structural integrity of the components, reduces their service life, and may lead to functional failures. In severe cases, it can even result in transmission slipping or complete transmission failure.

Harsh driving conditions and operational demands

Slippery road surfaces:Snow and ice on roads in winter make driving conditions more challenging. Wheels are prone to slipping during acceleration, and the electric transaxle needs to constantly adjust the distribution of power to the wheels to maintain traction. This increases the load on the transaxle and can cause wear and tear on components such as the differential and gears.

Frequent braking and acceleration:To ensure driving safety on slippery roads, drivers often need to brake and accelerate more frequently. These actions subject the electric transaxle to greater stress and heat generation, accelerating the wear of components and potentially leading to transmission failures.

Potential issues with integration and compatibility

Battery integration problems:The electric transaxle is closely integrated with the vehicle’s battery system. In winter, the performance of the battery may decline, which can affect the power output and control of the electric transaxle. Additionally, issues with the battery management system or charging system may impact the normal operation of the transaxle.

Compatibility with auxiliary systems:The performance of other auxiliary systems in the vehicle, such as the electronic stability control system and the anti-lock braking system, can also be affected by low temperatures. This may lead to compatibility issues with the electric transaxle, affecting the vehicle’s overall driving performance and safety.

Conclusion

In winter, electric transaxles face numerous challenges, including reduced battery performance, changes in lubricant viscosity, limitations of thermal management systems, increased condensation and corrosion risks, harsh driving conditions, and integration and compatibility issues. To mitigate these challenges, vehicle manufacturers and users can take several measures. For manufacturers, optimizing the thermal management system design, selecting high-performance lubricants, and improving the cold resistance of components are essential. For users, preheating the vehicle before use, using appropriate charging strategies, parking the vehicle in warm garages when possible, and performing regular maintenance can help ensure the normal operation and longevity of the electric transaxle in winter.

Post time: May-19-2025