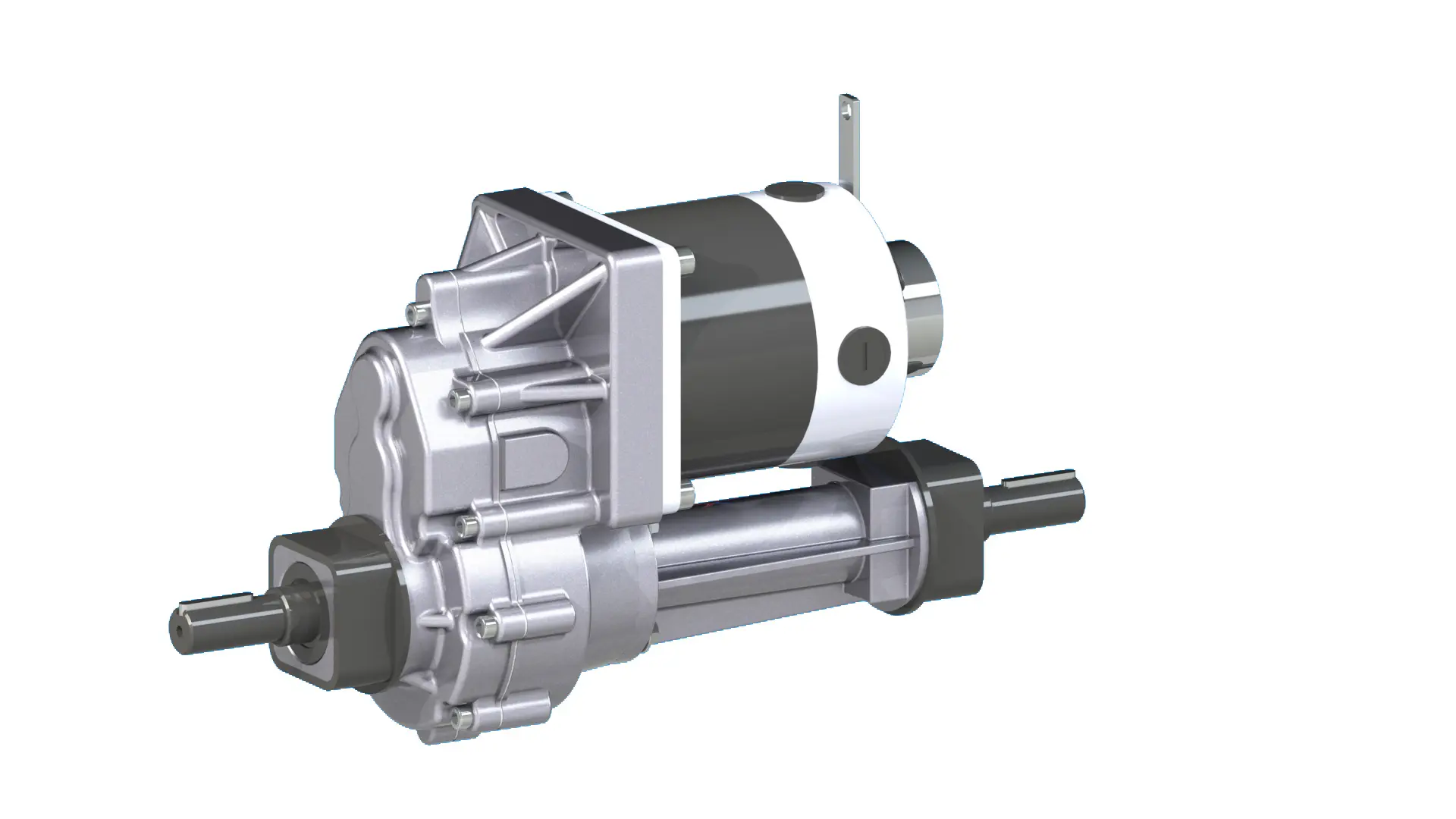

Electric transaxles are crucial components in cleaning vehicles, as they are responsible for transmitting power from the electric motor to the wheels. The materials used in their construction significantly affect performance, durability, and overall efficiency. Here are some common materials used for electric transaxles in cleaning vehicles:

1. Steel

Steel is widely used in the construction of transaxle housings and gears due to its high strength and durability. It can withstand high loads and is resistant to wear and tear, making it an excellent choice for heavy-duty cleaning vehicles. Steel components are also relatively inexpensive and easy to manufacture .

2. Aluminum

Aluminum is often used for transaxle housings and other components due to its lightweight properties. This material can improve fuel efficiency and reduce the overall weight of the vehicle, which is particularly beneficial for electric cleaning vehicles that need to optimize battery life. However, aluminum may not be as strong as steel and can be more susceptible to wear under high loads .

3. Cast Iron

Cast iron is sometimes used for transaxle housings due to its excellent heat dissipation properties and good wear resistance. It is heavier than aluminum but provides a robust and durable housing, making it suitable for high-performance cleaning vehicles that operate under demanding conditions .

4. Forged Parts

Forged parts, such as gears and shafts, are made by heating metal and then shaping it through forging. This process results in a denser grain structure, making the components stronger and more durable. Forged parts are often used in electric transaxles to ensure they can handle high torque and loads .

5. Powder Metallurgy

Some transaxle components, such as gears and bearings, are made through powder metallurgy. This process involves compacting metal powders and then sintering them at high temperatures. Components made through powder metallurgy can have a uniform material structure, leading to improved strength and wear resistance .

6. Synthetic Materials

Some transaxle components, such as seals and gaskets, are made from synthetic materials like rubber or polymers. These materials can provide good sealing properties and resistance to various environmental conditions, ensuring the transaxle operates smoothly and efficiently .

7. Heat Treatment

While not a material itself, heat treatment is a process applied to metals to improve their mechanical properties, such as hardness, strength, and wear resistance. This can be crucial for components that are subjected to high loads and stresses, ensuring the transaxle can perform reliably over time .

8. Lubricants

Lubricants play a vital role in the performance and durability of transaxles. They reduce friction between moving parts, which can help prevent wear and extend the life of the components. High-quality lubricants are essential for maintaining the efficiency and longevity of electric transaxles in cleaning vehicles .

Conclusion

The choice of materials for electric transaxles in cleaning vehicles depends on various factors, including the specific requirements of the vehicle, the operating conditions, and the desired performance characteristics. By selecting the right materials and combining them effectively, manufacturers can ensure that electric transaxles deliver optimal performance and durability, contributing to the overall efficiency and reliability of cleaning vehicles.

If you have any questions about electric transaxles or need further information, feel free to reach out. We are always here to help!

Post time: Mar-03-2025