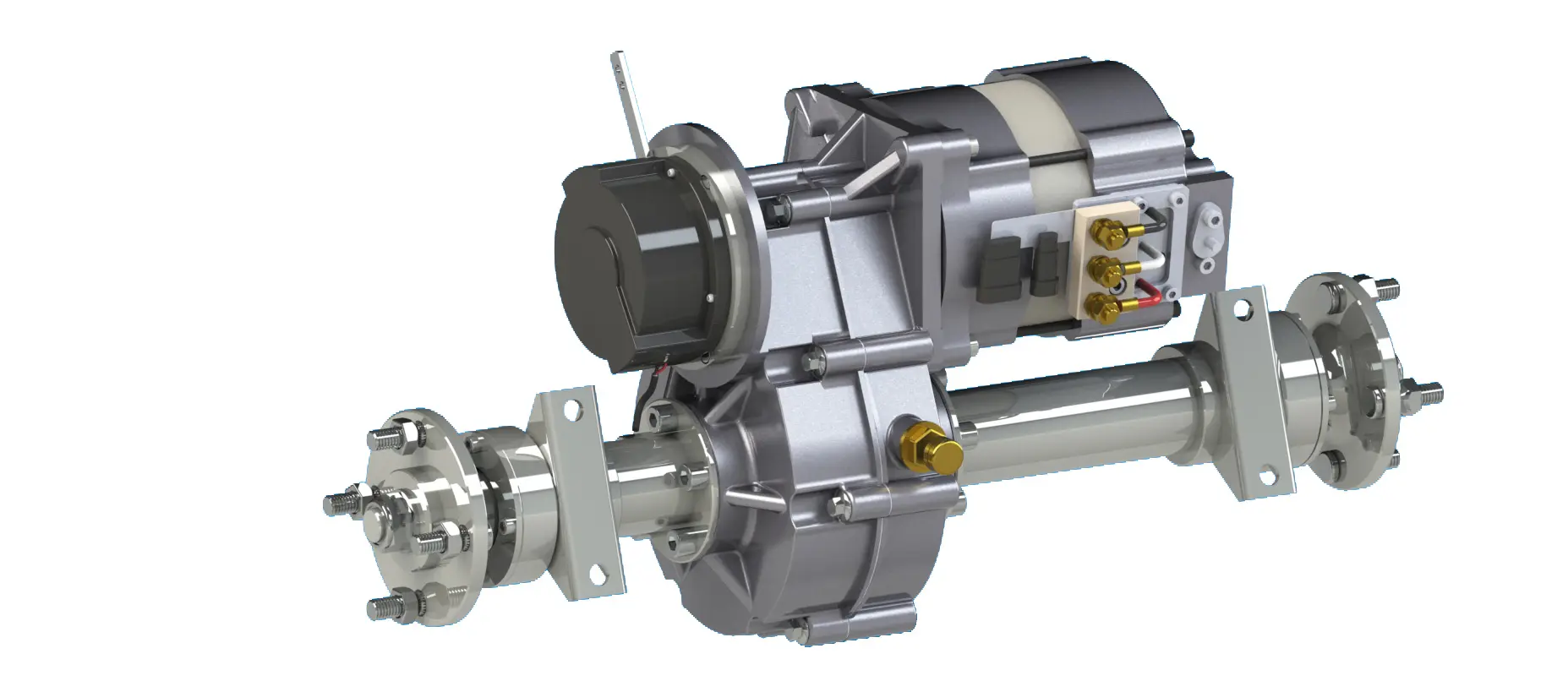

Transaxle DC Motor Production Process Detailed Explanation

Transaxle DC Motor is a DC drive shaft, which is an important power component of electric vehicles. Its production process is complex and precise. The following is a detailed introduction:

1. Design and Development

Conceptual Design: Engineers use CAD software to draw a three-dimensional model of the electric drive shaft, preliminarily determine the layout, shape and size of each component, and consider the compatibility and interface design with other vehicle systems.

Detailed Design and Simulation Analysis: Detailed design of key parameters of each component, such as the module, number of teeth, and tooth shape of the gear, the stator and rotor structure of the motor, and the transmission ratio of the reducer. Then, with the help of computer simulation software, such as finite element analysis (FEA), the stress distribution and deformation of key components such as gears and shafts under high load are evaluated to ensure their strength and reliability; the vibration and noise characteristics of the transmission system are studied through multi-body dynamics simulation to optimize the NVH performance of the system; motor performance simulation is performed to predict key indicators such as efficiency, torque output and temperature rise of the motor under different working conditions, providing a basis for subsequent optimization design.

2. Parts Processing and Manufacturing

Motor Stator and Rotor Manufacturing: Stator manufacturing generally adopts the lamination process. Silicon steel sheets are stacked into stator punching sheets according to design requirements, and then insulating materials are embedded in the punching sheet slots and coils are wound. High-precision winding equipment is required to wind the coils to ensure that the number of turns, pitch and distribution of the coils are uniform to achieve efficient operation of the motor. For the rotor of the permanent magnet synchronous motor, high-performance permanent magnets need to be embedded in the punching sheets, and precise pole magnetization is performed. The size, position and magnetic properties of the permanent magnets are strictly controlled. At the same time, the rotor needs to be dynamically balanced to ensure stability during high-speed rotation and avoid vibration and noise problems.

Gear processing and heat treatment: Gear processing accuracy and performance requirements are extremely high, and it is divided into two stages: rough processing and fine processing. Rough processing uses forging or precision casting to make the blank material into a gear rough shape close to the final shape; fine processing uses CNC machine tools (CNC) to accurately cut the tooth shape to ensure that the gear tooth surface accuracy, circumferential cumulative error and contact accuracy meet the design requirements. In order to improve the surface hardness and wear resistance of the gears while maintaining the toughness of the core, professional heat treatment is required. Common methods include carburizing and quenching and nitriding. Carburizing and quenching is carburizing in a high-temperature furnace to form a hardened layer with a high carbon concentration on the surface, and then quickly quenching and cooling; nitriding is to allow nitrogen atoms to penetrate the surface of the gear at high temperature to form a hard and wear-resistant nitrided layer. The heat-treated gears also need to be precisely ground and honed to further improve the tooth surface finish and precision.

Reducer housing and differential manufacturing: As a supporting structure, the reducer housing must have sufficient strength and rigidity, while taking into account lightweight design. It is usually made of aluminum alloy or high-strength steel and is formed by casting, forging or precision stamping. During the processing, the size and shape and position tolerances are strictly controlled to ensure the assembly accuracy with internal components. The gear set of the differential includes planetary gears, axle gears and differential housings, etc. The processing accuracy requirements are extremely high. It needs to be processed by high-precision machine tools and undergoes strict testing and assembly. Lubrication and sealing are also required during the assembly process.

3. Assembly and debugging

Parts pre-assembly and testing: According to the design drawings and process requirements, the main components such as motors, reducers and differentials are preliminarily assembled, and the matching between the components is checked to see if there is interference or looseness. In addition, key components are tested for performance, such as the no-load current and speed of the motor, the transmission efficiency and noise of the reducer, etc., to ensure that each component meets the quality standards before entering the final assembly stage.

General assembly and torque calibration: The assembly workers strictly follow the process flow to accurately install each component to the specified position and use a professional torque wrench to calibrate the torque of the connecting bolts. There are strictly specified torque values for different bolt connection parts. Excessive or small torque will affect product reliability and safety. At the same time, carefully check the lubrication system and sealing system of the electric drive transmission shaft to ensure that the filling amount and distribution of grease are reasonable to avoid poor lubrication and wear of components; check the sealing performance of each sealing part to prevent oil leakage or water ingress, and ensure the normal operation of the electric drive transmission shaft under various working conditions.

Vehicle matching and performance debugging: Install the electric drive shaft on the prototype vehicle and conduct a series of vehicle performance tests and debugging, including power output characteristic tests, check the torque output and power matching of the electric drive shaft under different vehicle speeds and load conditions; perform power performance tests under acceleration, deceleration and climbing conditions, optimize the motor control strategy and the transmission ratio of the reducer; evaluate and debug the NVH performance of the vehicle, and reduce the vibration and noise of the transmission system and improve driving comfort by adjusting the gear meshing clearance and optimizing the electromagnetic compatibility of the motor.

4. Quality inspection and finished product packaging

Appearance and size inspection: Strictly check the appearance of the electric drive shaft to check whether there are scratches, abrasions, rust spots and other appearance defects on the product surface to ensure that the appearance quality meets customer requirements. At the same time, use high-precision measuring instruments to measure the key dimensions of the product, including the dimensional accuracy of the installation interface, wheelbase, gear module and number of teeth, etc., to ensure that it is within the allowable tolerance range and meets the assembly requirements with the vehicle and other components.

Performance and function testing: Conduct comprehensive performance and function tests on the electric drive shaft, such as insulation resistance test, torque test, temperature rise test, etc., to ensure that its performance meets the design requirements and relevant standards and specifications, and can meet the operation requirements of the vehicle under various working conditions.

5. Key technologies and development trends in the production process

Automated production technology: In the production of Transaxle DC Motor, more and more companies are introducing automated production lines, such as using robots and automated equipment in stator winding, rotor assembly, gear processing and other links to improve production efficiency and product consistency, and reduce labor costs and human errors.

Application of new materials: Research and development and application of high-performance motor materials, such as high-strength and high-magnetic conductivity silicon steel sheets, high-conductivity copper wires, and high-temperature and wear-resistant insulation materials, will help improve the performance and efficiency of the motor, while reducing weight and enhancing reliability.

Integrated and modular design: The integrated design of motors, reducers, controllers and other components forms a compact modular structure, which not only saves space and improves the overall layout flexibility of the vehicle, but also helps to simplify the production and assembly process, improve production efficiency and product quality, and also facilitate subsequent maintenance and replacement.

Digitalization and intelligent manufacturing: Use digital technology to monitor and manage the production process in real time, optimize production process parameters through big data analysis and artificial intelligence algorithms, realize intelligent production scheduling and quality control, improve production efficiency and product quality stability, and reduce production costs.

In short, the production process of Transaxle DC Motor is a multi-link, high-precision, complex and systematic project, and its production technology level directly affects the performance and quality of products such as electric vehicles. With the continuous development and innovation of technology, the production process will continue to be improved and optimized, driving the electric vehicle industry towards higher performance and higher efficiency.

Post time: Apr-21-2025