Introduction

In the rapidly evolving automotive industry, the shift from traditional internal combustion engine (ICE) vehicles to electric vehicles (EVs) is gaining momentum. One of the key components driving this transition is the electric transaxle.

Understanding Electric Transaxles and Traditional Drivetrains

Electric Transaxles

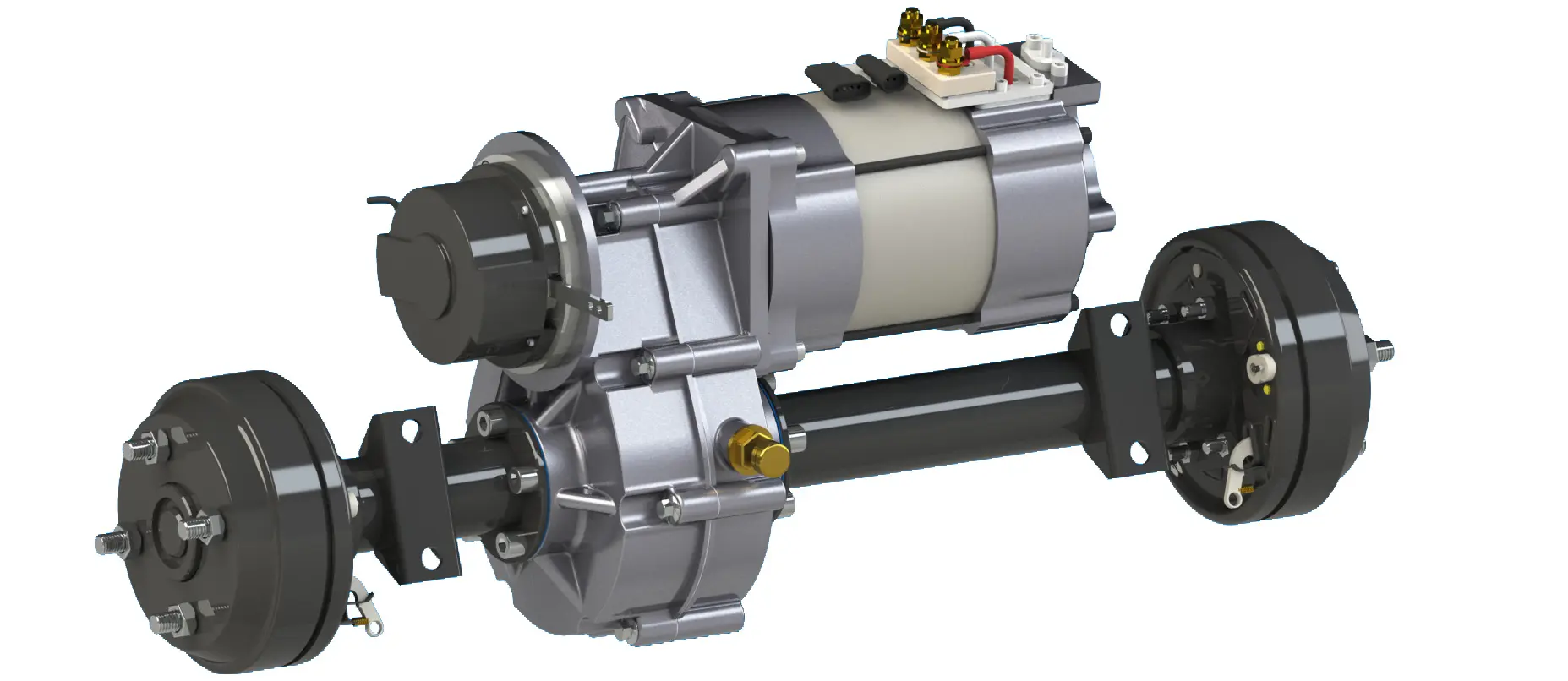

An electric transaxle, also known as an e-transaxle or e-axle, is a highly integrated system that combines an electric motor, transmission, and differential into a single unit. This design is significantly different from traditional drivetrains, which typically consist of a complex assembly of components, including the engine, clutch, gearbox, and exhaust system. The electric transaxle operates by integrating the electric motor directly with the transmission and differential, providing

immediate torque and smooth power delivery.

Traditional Drivetrains

Traditional drivetrains are based on internal combustion engines, which require a multi-speed transmission to manage different speeds and torque requirements. These systems include a variety of moving parts such as the engine, clutch, gearbox, and exhaust system, all of which contribute to mechanical complexity and higher maintenance requirements.

Maintenance Cost Comparison

Fewer Moving Parts

One of the most significant differences between electric transaxles and traditional drivetrains is the number of moving parts. Electric transaxles have fewer moving parts compared to traditional transmissions, which reduces the chances of mechanical failures and wear and tear. For example, a typical electric transaxle may have around 20 moving parts, whereas a traditional drivetrain can have over 200. This reduction in complexity leads to lower maintenance costs and longer lifespans for electric transaxles.

Regenerative Braking Systems

Electric vehicles commonly incorporate regenerative braking systems that use the electric motor to slow down the vehicle while simultaneously converting kinetic energy into electrical energy. This reduces the workload on the traditional braking system, extending the life of the brakes and reducing the frequency of brake replacements. In contrast, traditional vehicles rely solely on friction brakes, which wear out more quickly and require more frequent maintenance.

Fluids and Filters

Traditional vehicles rely on a range of fluids such as engine oil, transmission fluid, and coolant, as well as various filters to ensure the cleanliness of these fluids. Electric vehicles, on the other hand, eliminate the need for many of these fluids, simplifying maintenance routines and reducing associated costs. For example, electric transaxles do not require regular oil changes or transmission fluid replacements.

Software-Based Control

Electric vehicles often rely on sophisticated software systems to manage the motor and power distribution. These control units can optimize efficiency, manage energy flow, and adapt to real-time driving conditions, enhancing the vehicle’s overall performance. In contrast, traditional vehicles may require extensive mechanical repairs to address performance issues, making EV maintenance not only cost-effective but also more convenient.

Battery Maintenance

While electric transaxles themselves require minimal maintenance, the battery system in electric vehicles is a crucial component that requires attention. Proper battery care, including controlled charging routines and avoiding deep discharges, is essential to maximize battery life and vehicle range. However, advancements in battery technology and management systems are continually improving battery longevity and reducing maintenance costs.

Cost Analysis

Initial Purchase Price

While the initial purchase price of electric vehicles may be higher than that of traditional vehicles, the total cost of ownership can be lower due to lower maintenance costs and energy efficiency. Over the lifetime of the vehicle, these savings can be significant, making electric transaxles a more cost-effective choice for long-term use.

Maintenance Frequency

Electric transaxles generally require less frequent maintenance compared to traditional drivetrains. For example, electric transaxles may only need maintenance every 5,000 to 10,000 miles or every six months, while traditional drivetrains often require more frequent inspections and fluid changes. This reduced maintenance frequency translates to lower labor costs and less downtime for vehicles.

Long-Term Savings

Over the long term, the lower maintenance costs associated with electric transaxles can result in significant savings for fleet operators and wholesale buyers. Studies indicate that EV drivers save approximately 40% on repair and maintenance expenses compared to ICE vehicle owners. These savings, combined with lower fuel costs due to the efficiency of electric motors, make electric transaxles an attractive option for those looking to minimize long-term operational costs.

Environmental Impact

In addition to cost savings, electric transaxles also offer environmental benefits. Electric vehicles produce zero tailpipe emissions, making them more environmentally friendly than traditional vehicles. This reduction in emissions can be particularly important for companies looking to reduce their carbon footprint and comply with stricter environmental regulations.

Conclusion

The shift from traditional drivetrains to electric transaxles represents a significant advancement in automotive technology. While the initial investment in electric vehicles may be higher, the long-term savings in maintenance costs and operational expenses make electric transaxles an attractive option for international wholesale buyers and fleet operators. By reducing the number of moving parts, incorporating regenerative braking systems, and eliminating the need for frequent fluid changes, electric transaxles offer a more cost-effective and environmentally friendly solution compared to traditional drivetrains.

As the automotive industry continues to evolve, the technology behind electric transaxles is constantly improving. Manufacturers are focusing on enhancing efficiency, performance, and durability, making electric transaxles an increasingly viable choice for a wide range of applications. For those considering the transition to electric vehicles, the lower maintenance costs and environmental benefits of electric transaxles make them a compelling option for the future of transportation.

Post time: Jul-21-2025