In-depth exploration of the 1.5KW floor grinding and polishing machine gearbox: core essence and comprehensive analysis

In the field of floor grinding and polishing, the 1.5KW floor grinding and polishing machine has become the favorite choice of many professional construction personnel and related companies due to its excellent performance and wide application. The gearbox, as one of the core components of the equipment, plays a vital role. This article will deeply analyze the various aspects of the 1.5KW floor grinding and polishing machine gearbox to take you to appreciate its unique charm.

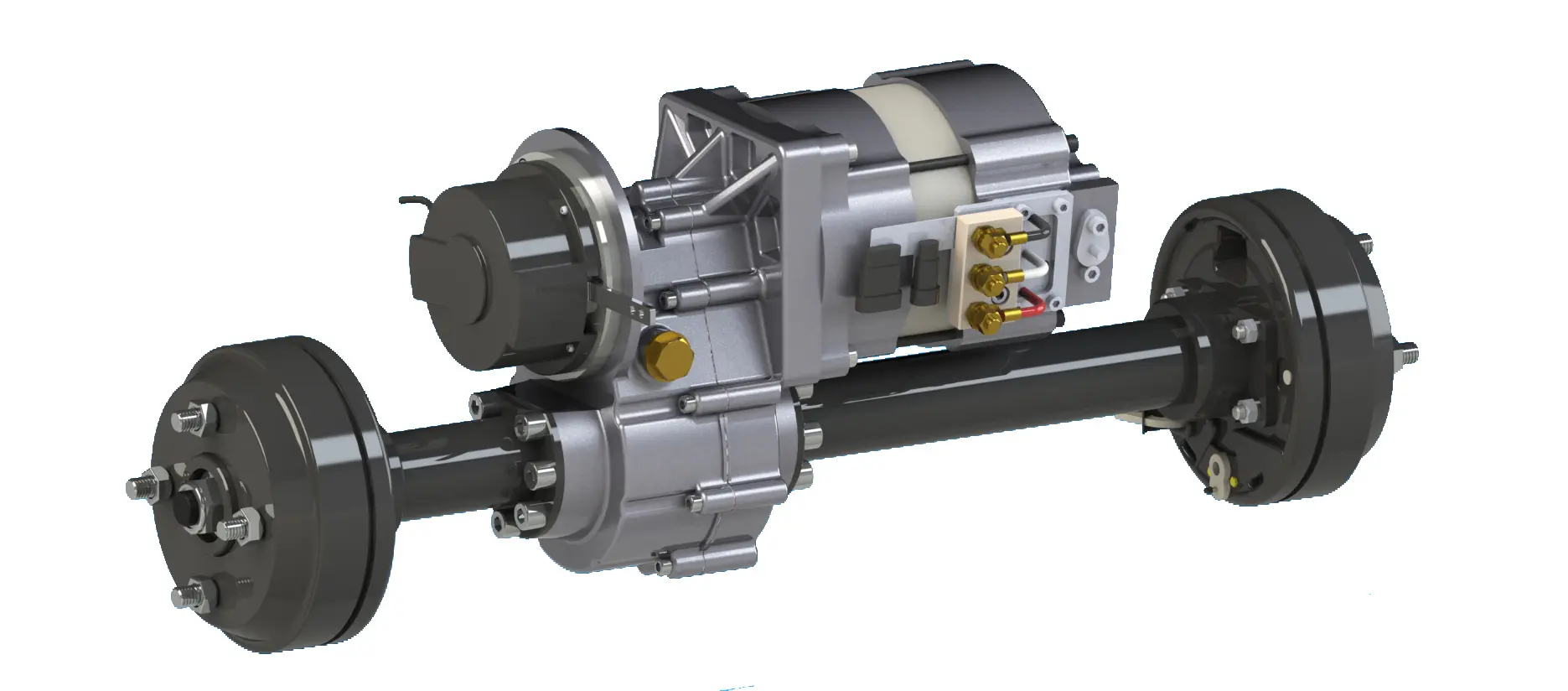

1. The basic structure and working principle of the gearbox

Basic structure

The 1.5KW floor grinding and polishing machine gearbox is mainly composed of key components such as gear sets, bearings, shafts, and housings. The gear set is usually made of high-quality alloy steel materials, which are finely processed and heat treated to ensure its stability and durability under high-intensity operation. The bearings are made of high-precision, low-noise ball bearings or roller bearings, which can effectively support the rotation of the gears and reduce friction losses. The material of the shaft is generally high-quality carbon steel that has been quenched and tempered, with good strength and toughness, and can withstand the transmission of torque. The box is mostly made of high-strength cast iron or aluminum alloy materials, with good rigidity and sealing, providing reliable protection and stable support for internal components.

Working principle

When the 1.5KW motor is started, the power is transmitted to the input shaft of the gearbox through the coupling, and then the gear on the input shaft meshes with other gears inside the gearbox to achieve torque transmission and speed conversion. Through the combination of different gears, the gearbox can output a variety of different speeds to meet the needs of different stages and different materials of floor during floor grinding and polishing. For example, when rough grinding harder wooden floors, a lower speed can be used to obtain greater torque, thereby improving grinding efficiency; while when fine polishing softer composite floors, a higher speed can be used to make the polishing effect more delicate and uniform.

2. Key performance indicators and advantages of the gearbox

Transmission efficiency

The transmission efficiency of the high-quality 1.5KW floor grinding and polishing machine gearbox can reach more than 90%, which means that the power output by the motor can be transmitted to the grinding and polishing disc to the maximum extent, reducing energy loss and improving the overall working efficiency of the equipment. An efficient transmission system can not only save energy consumption, but also achieve faster grinding and polishing speed under the same power input, shorten working time, and thus improve the overall progress and output of the construction project.

Torque output range

This type of gearbox can usually provide a wide torque output range, generally between 10 and 50 Nm, which can be flexibly adjusted according to different floor materials and construction processes. When facing some hard stone floors or severely worn old floors for renovation, the larger torque output can make the grinding and polishing machine easy to deal with, ensuring that the grinding tool can effectively cut into the floor surface, remove old coatings, scratches and flaws, and lay a good foundation for subsequent polishing processes; when dealing with some more delicate floor materials, such as solid wood composite floors or bamboo floors, the smaller torque output can avoid excessive damage to the floor and achieve a more refined grinding effect.

Speed Shift Stability

Stable speed shifting performance is a major advantage of the 1.5KW floor grinding and polishing machine gearbox. In the actual construction process, the condition and construction requirements of the floor may change at any time, requiring operators to be able to quickly and smoothly adjust the speed of the equipment. High-quality gearboxes can achieve smooth switching between different speed gears without obvious setbacks or speed fluctuations, thus ensuring the consistency and uniformity of the grinding and polishing process. For example, when performing multiple grinding processes on the floor, from coarse grinding to fine grinding to polishing, the operator can easily increase the speed step by step through a stable gearbox, so that the grinding effect of each stage can reach the best state, avoiding problems such as uneven grinding marks and poor polishing effect caused by unstable speed.

Noise and vibration control

The 1.5KW floor grinding and polishing machine gearbox focuses on noise and vibration control during the design and manufacturing process. By adopting optimized gear tooth design, high-precision processing technology and effective shock absorption and buffering measures, the noise level of the gearbox during operation can be controlled in a low range, generally not exceeding 75 decibels, providing operators with a relatively comfortable working environment and reducing the impact of noise on the operator’s hearing and physical and mental health. At the same time, good vibration control is also conducive to improving the stability and service life of the equipment, preventing problems such as loose parts, increased wear and uneven grinding and polishing due to excessive vibration.

3. The important role of the gearbox in floor grinding and polishing

Adapting to different floor materials and construction processes

Different types of floors, such as solid wood floors, laminate floors, marble floors, tile floors, etc., have different material characteristics, hardness and surface treatment requirements. The 1.5KW floor grinding and polishing machine gearbox can adjust the speed and torque output according to these differences to make the equipment suitable for grinding and polishing of various floors. For example, for solid wood floors, their texture is relatively soft, but during the grinding process, it is necessary to pay attention to the protection of the wood texture. At this time, medium speed and moderate torque can be used for grinding to avoid damaging the wood surface; while for marble floors, their hardness is high and the surface finish requirements are high. In the early stage of grinding, it is necessary to use a lower speed and a larger torque for rough grinding, gradually remove the unevenness and scratches on the ground, and then gradually increase the speed and cooperate with finer grinding tools for fine grinding and polishing, and finally achieve a mirror effect. This adaptability of the gearbox enables the 1.5KW floor grinding and polishing machine to meet the diverse needs of different customers in different scenarios, and become an essential equipment in floor renovation, decoration projects and daily maintenance.

Improve the quality and efficiency of grinding and polishing

During the floor grinding and polishing process, the performance of the gearbox directly affects the quality and efficiency of grinding and polishing. An efficient gearbox can ensure the stable transmission of power, so that the grinding and polishing disc contacts the floor at a suitable speed and pressure, thereby achieving a more uniform and thorough grinding effect. For example, when renovating a large area of commercial building floors, using a 1.5KW floor grinding and polishing machine equipped with a high-quality gearbox can quickly remove the old wear layer, level the floor, and quickly achieve the required gloss and smoothness in the subsequent polishing process, greatly improving construction efficiency and shortening project duration. At the same time, the stable speed change function can also avoid problems such as uneven grinding marks and insufficient polishing caused by unstable equipment speed, ensuring that the appearance and performance of the floor after grinding and polishing can meet high standards, improving the quality and customer satisfaction of the entire construction project.

Extend equipment service life and reduce maintenance costs

The reliability and durability of the high-quality 1.5KW floor grinding and polishing machine gearbox help extend the overall service life of the equipment. The high-quality materials and exquisite manufacturing process used can ensure that the gearbox maintains good performance under long-term and high-intensity operation, reducing the frequency of failures. For example, the optimized gear set and reliable bearing configuration can effectively reduce the wear rate of components and ensure the transmission accuracy and stability inside the gearbox. In addition, good sealing and effective lubrication system also help reduce the erosion and damage of dust, debris and moisture to the internal components of the gearbox, further improving the service life of the gearbox. For users, this means reducing the replacement frequency and maintenance time of equipment, and reducing the overall cost of equipment purchase and maintenance. At the same time, stable gearbox operation is also conducive to reducing construction delays and additional economic losses caused by equipment failure, and improving the return on investment of equipment.

4. How to choose a high-quality 1.5KW floor grinding and polishing machine gearbox

Brand and manufacturer reputation

When choosing a 1.5KW floor grinding and polishing machine gearbox, the reputation of the brand and manufacturer is one of the important considerations. Well-known manufacturers usually have more R&D and production experience, stricter quality control systems and more complete after-sales service networks. The gearboxes they produce have been tested by the market for a long time, and their performance and reliability have been recognized by the majority of users. For example, some internationally renowned brands have many years of professional accumulation in the field of floor grinding and polishing equipment, and their products are renowned worldwide for their excellent quality and performance. Choosing these brands of gearboxes, users can get more stable product quality and more reliable after-sales support, such as timely technical consultation, parts supply and maintenance services, etc., to ensure the normal operation and long-term use of the equipment.

Transmission accuracy and stability

Transmission accuracy and stability are key indicators for measuring the quality of gearboxes. In the actual purchase process, the transmission performance of the gearbox can be evaluated by checking the gear processing accuracy, assembly quality and operation test report of the gearbox. High-precision gear processing can ensure the meshing accuracy between gears, reduce transmission errors and noise, and improve transmission efficiency and stability. At the same time, good assembly quality is also the basis for ensuring the normal operation of the gearbox, including the accuracy of the installation position of parts, the degree of tightening, and the rationality of the lubrication system. In addition, the manufacturer can also be asked to provide the operation test data of the gearbox to observe its stability performance under different speeds and load conditions, such as whether there are obvious vibrations, abnormal noises or speed fluctuations. Choosing a gearbox with high transmission accuracy and good stability can effectively improve the overall performance and service life of the floor grinding and polishing machine, and provide users with a better use experience.

Material and durability

The material of the gearbox is directly related to its durability and service life. The gears of high-quality gearboxes are usually made of high-strength alloy steel and undergo fine forging, heat treatment and processing to ensure that they have sufficient hardness, toughness and wear resistance. The box material is mostly made of high-strength cast iron or aluminum alloy, which has good rigidity and deformation resistance, and can provide reliable protection and stable support for internal components. When choosing, you can ask the manufacturer about the specific material and manufacturing process of the gearbox, and ask for relevant material test reports and quality assurance certificates. In addition, you can also refer to the use evaluation and feedback of other users to understand the durability and reliability of gearboxes of different brands and models in actual use, so as to choose a product that is more suitable for you.

After-sales service and accessories supply

Good after-sales service and sufficient accessories supply are important guarantees to ensure the long-term and stable operation of the 1.5KW floor grinding and polishing machine gearbox. When purchasing a gearbox, you should choose manufacturers or suppliers that provide perfect after-sales service, including timely technical support, repair services, regular maintenance guidance, and spare parts supply. For example, can the manufacturer provide a quality warranty within a certain period of time? Can it respond quickly and provide professional repair solutions when the equipment fails? Can it supply original accessories in a long-term and stable manner to meet the maintenance and replacement needs of the equipment? These are the issues that users need to focus on when choosing a gearbox. High-quality after-sales service and sufficient supply of spare parts can reduce the downtime of the equipment, reduce maintenance costs, and ensure that the user’s construction project can proceed smoothly.

V. Maintenance and maintenance points of the 1.5KW floor grinding and polishing machine gearbox

Regular inspection and cleaning

Regular inspection and cleaning of the 1.5KW floor grinding and polishing machine gearbox is one of the important measures to ensure its normal operation. During use, dust, wood chips, abrasive particles and other debris easily enter the gearbox, accumulate on the gears, bearings and the inner wall of the box, affect the heat dissipation and lubrication effect of the gearbox, and accelerate the wear of components. Therefore, it is recommended that users conduct a detailed inspection and cleaning of the gearbox every week or after completing a certain amount of work. First, turn off the power of the equipment and wait for the gearbox to cool completely, then open the inspection hole of the gearbox or remove part of the outer shell, and use a clean cloth or brush to remove the dust and debris inside. For stubborn dirt that is difficult to clean, you can use an appropriate amount of special cleaning agent to clean it, but be careful to avoid the cleaning agent entering the bearing and gear meshing parts to avoid affecting the lubrication performance. After cleaning, carefully check whether there is wear, cracks or pitting on the gear surface, whether the bearing is loose, overheated or abnormally worn, etc. If any problems are found, repair or replace the parts in time.

Replacement and maintenance of lubricating oil

Lubricating oil is one of the key factors to ensure the normal operation of the 1.5KW floor grinding and polishing machine gearbox. High-quality lubricating oil can form a protective film on the surface of gears and bearings, reduce friction loss, reduce wear rate, dissipate heat and prevent rust. Generally speaking, the lubricating oil of a newly purchased gearbox should be replaced within 50 to 100 hours of work after the first use, and then every 200 to 300 hours or according to the manufacturer’s recommendation. When replacing the lubricating oil, you should choose the lubricating oil model and viscosity grade that meet the manufacturer’s requirements, and ensure that the lubricating oil is of qualified quality and uncontaminated. At the same time, pay attention to the correct discharge of the old lubricating oil. After the waste oil in the gearbox is completely drained, add an appropriate amount of new lubricating oil to avoid mixing new and old oils and affecting the lubrication effect. In addition, in daily use, the level and quality of the lubricating oil should be checked regularly. If the oil level is too low, the oil color turns black, or impurities are mixed in, the lubricating oil should be replenished or replaced in time to ensure the good lubrication of the gearbox.

Avoid overloading and overspeeding

Overloading and overspeeding are one of the common causes of gearbox failure and damage of 1.5KW floor grinding and polishing machines. In actual operation, the operator should strictly follow the equipment’s instruction manual and the manufacturer’s recommended parameters to avoid applying a load that exceeds its rated load capacity to the floor grinding and polishing machine, and at the same time control the speed of the equipment within the range allowed by the gearbox. For example, when encountering a particularly hard floor or a large ground obstacle, do not forcibly increase the throttle or pressure of the equipment to avoid overloading the gearbox, resulting in serious faults such as gear knocking and bearing damage.

Post time: Apr-30-2025