In-depth exploration of electric drive shafts: opening a new era of vehicle performance and efficiency

In today’s rapidly developing automotive field, electric drive shafts are gradually becoming the focus of industry attention. For international wholesale buyers, it is crucial to have a deep understanding of the advantages of electric drive shafts, because this will not only help you provide customers with better products, but also make you stand out in a highly competitive market. This article will take a deep look at the many advantages of electric drive shafts in vehicles.

Efficiency improvement: the powerful engine of vehicle performance

Direct energy transmission: The electric drive shaft simplifies the energy transmission path from the motor to the wheels, reduces the energy loss caused by multi-component transmission in traditional mechanical systems, and can efficiently convert more than 90% of the battery energy into vehicle movement power, far exceeding the efficiency of traditional internal combustion engines.

Accurate power regulation: According to different driving conditions, the electric drive shaft can adjust the torque distribution in real time to ensure the rational use of power, thereby reducing energy waste, improving battery efficiency, and extending vehicle range.

Regenerative Braking Assist: It is perfectly compatible with the regenerative braking system. When the vehicle decelerates, the kinetic energy that would otherwise be lost during braking can be converted into electrical energy and stored in the battery, further optimizing the energy utilization efficiency of the entire vehicle and extending the vehicle’s range.

Excellent performance: Driving an extraordinary driving experience

Instant torque, strong acceleration: The electric motor has the characteristic of instant torque output. The electric drive shaft can give full play to this advantage, allowing the vehicle to respond quickly when starting and accelerating, bringing the driver a strong and continuous acceleration experience, surpassing the acceleration performance of many traditional fuel vehicles.

Precise control, excellent handling: The electric drive shaft is combined with an advanced vehicle control system to achieve precise distribution of torque to each wheel, thereby improving the stability and handling of the vehicle under various road conditions. Whether it is a sharp turn, slippery road or high-speed driving, the vehicle can maintain excellent balance and grip.

Excellent power performance: When the vehicle climbs a slope or carries heavy objects, the electric drive shaft can effectively utilize the high torque characteristics of the motor to ensure that the vehicle can obtain sufficient power support under various working conditions. The power output is linear and easy to control, and the driver can accurately adjust the speed and torque according to needs.

Environmentally friendly: Implementing the mission of green transportation

Achieving zero emissions: The electric drive shaft is a key component of electric vehicles, and electric vehicles do not produce exhaust emissions during operation, which is of great significance to reducing air pollution and improving the quality of urban environment, and helps to achieve the goal of global green transportation.

Reduce noise pollution: Compared with the noisy operation of traditional fuel engines, the electric drive shaft has extremely low noise when working, creating a quieter and more comfortable driving environment for drivers and passengers, while also reducing noise interference to the surrounding environment and improving the quality of life of residents.

Easy maintenance: Reduce costs and improve reliability

Fewer parts and fewer failures: The electric drive shaft has a relatively simple structure, without the complex crankshaft, piston, valve and other parts of traditional fuel engines, and does not need to frequently replace consumables such as oil and oil filter, reducing potential failure points and reducing the complexity and workload of maintenance work.

Extended service life: Due to its simplified design and fewer wearing parts, the service life of electric drive shafts is usually longer than that of traditional transmission systems, reaching 150,000 miles or even further, saving car owners a lot of repair and replacement costs.

Maintenance cost savings: According to relevant research, the maintenance cost of electric vehicles equipped with electric drive shafts can be reduced by about 40% compared with traditional fuel vehicles, and with the continuous maturity of technology and the development of the market, this ratio is expected to increase further, bringing more considerable economic benefits to users.

Space optimization: design freedom and practical advantages

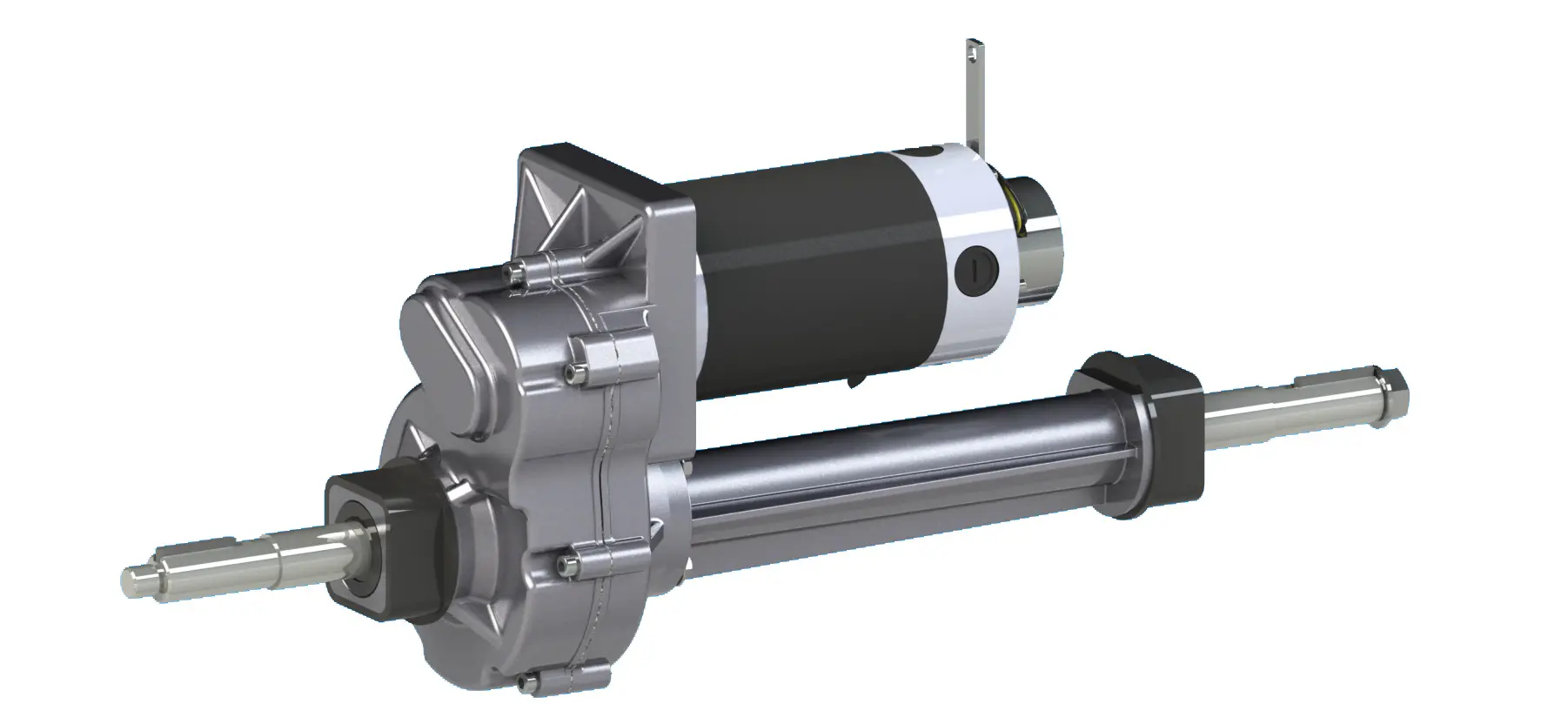

Compact design, flexible layout: The electric drive shaft integrates components such as motors, transmissions and differentials into one, greatly saving the mechanical space of the vehicle and providing greater freedom for the overall design of the vehicle. Manufacturers can use the saved space to optimize the vehicle layout, such as increasing battery capacity, improving the interior passenger space or increasing the luggage compartment volume, thereby improving the practicality and competitiveness of the vehicle.

Lightweight advantages: Its compact design is often accompanied by a reduction in weight, which not only helps to reduce the energy consumption of the vehicle, further improves energy efficiency and cruising range, but also has a positive impact on vehicle handling and performance, such as more flexible steering, shorter braking distance and better dynamic response.

Cost advantage: The only choice for long-term value

Purchase subsidies and preferential policies: In order to encourage the promotion and application of electric vehicles, many countries and regions will provide purchase subsidies, tax incentives and other policy support for consumers who purchase electric vehicles equipped with electric drive shafts, reducing consumers’ initial car purchase costs and increasing the market appeal of products.

Low energy cost: The operating cost of electric vehicles using electric drive shafts mainly comes from electricity, and electricity prices are usually cheaper than oil prices. In the long-term use process, the energy cost of electric vehicles can be reduced by about 60%-70% compared with traditional fuel vehicles, saving users a lot of use costs.

High residual value rate: With the continuous development and maturity of the electric vehicle market, the residual value rate of electric vehicles equipped with advanced electric drive shafts is also relatively high. This not only provides consumers with better economic returns when the vehicle is resold, but also adds important advantages to wholesale buyers in the process of product promotion and sales, because the high residual value rate means that the depreciation risk borne by consumers when purchasing is relatively low, and the investment value of the product is higher.

Safety performance: All-round protection of driving safety

Stable power output: The electric drive shaft can provide smooth and linear power output, avoiding the power interruption and impact that may occur during acceleration and shifting of traditional fuel engines, making the vehicle more stable during driving, reducing the risk of vehicle loss of control due to power fluctuations, and providing drivers and passengers with a more stable and safer driving experience.

Advanced braking system integration: It is combined with the regenerative braking system and other advanced braking technologies to achieve more efficient and accurate braking force distribution and control. In emergency braking, the vehicle has a shorter braking distance and more reliable braking effect, which effectively reduces the probability of accidents and ensures the life safety of drivers and passengers.

Reduced fire risk: Compared with traditional fuel engines, electric drive shafts do not have the risk of fuel leakage and combustion during operation, reducing the possibility of fire caused by fuel problems and improving the overall safety of the vehicle.

Intelligent integration: Leading the future driving trend

Intelligent control and energy management: The electric drive shaft can be deeply integrated with the vehicle’s intelligent control system to achieve real-time monitoring and intelligent adjustment of parameters such as motor power output, energy recovery, and torque distribution. Through intelligent algorithms and sensor technology, the vehicle can automatically optimize the working state of the drive shaft according to different driving scenarios and road conditions, improve energy efficiency, and provide drivers with a more intelligent and personalized driving experience.

OTA upgrade and performance optimization: The electric drive shaft that supports OTA (Over-the-Air) technology can continuously optimize its control logic and performance through remote software updates. This means that the vehicle’s transmission system can continue to upgrade with the advancement of technology, and consumers can enjoy more advanced functions and better performance without replacing hardware, which improves the product’s service life and competitiveness, and also reduces the vehicle’s full life cycle cost.

Automatic driving assistance: In the development of autonomous driving technology, the precise control and rapid response capabilities of the electric drive shaft play an important role. It can better cooperate with the instructions of the autonomous driving system to achieve precise power output and vehicle control, provide reliable power support and safety guarantees for the realization of autonomous driving, and promote the future development of automobiles towards intelligence and autonomous driving.

Vehicle compatibility: unlimited potential for wide application

Adaptable to a variety of vehicle models: Electric drive shafts have a wide range of vehicle compatibility. Whether it is a sedan, SUV, commercial vehicle or engineering vehicle, it can be equipped with a suitable electric drive shaft system according to specific needs. This provides automakers with more design and production flexibility, enabling them to quickly launch electrified models that meet different market needs, and also provides wholesale buyers with a rich product selection and a broader market space.

The perfect partner for hybrid systems: In hybrid vehicles, electric drive shafts can be seamlessly integrated with the internal combustion engine transmission system to achieve complementary advantages of the two power sources. It can switch freely between pure electric mode and hybrid mode according to the vehicle’s driving status and power requirements, which not only ensures the vehicle’s cruising range, but also gives full play to the advantages of electric drive shafts in acceleration performance, fuel economy, etc., providing consumers with more efficient and environmentally friendly travel solutions.

Market trends: Seize the opportunity for industry development

Demand is growing rapidly: With the increasing global attention to environmental protection and sustainable development, as well as the increasing maturity of electric vehicle technology and the gradual reduction of costs, the electric vehicle market is showing a rapid growth trend. As one of the core components of electric vehicles, the market demand for electric drive shafts has also increased significantly, bringing broad development opportunities to related companies.

Technological innovation drives industry progress: In order to meet the growing market demand for electric drive shafts, many scientific research institutions and companies are increasing their R&D investment, committed to improving the performance, reliability and durability of electric drive shafts and reducing production costs. For example, the development of higher power density motor technology, more efficient transmission design and more advanced cooling systems, these technological innovations will further enhance the overall performance and competitiveness of electric vehicles and promote the rapid development of the industry.

Coordinated development of the industrial chain: The industrial development of electric drive shafts will also drive the coordinated development of upstream and downstream related industrial chains, such as battery technology, charging facilities, intelligent control systems and other fields. This will form a huge industrial cluster, create more value for economic growth, and provide more cooperation opportunities and development space for wholesale buyers, promoting the prosperity of the entire industry.

Conclusion

As one of the core technologies of electric vehicles and hybrid vehicles, electric drive shafts are leading the automotive industry to a more efficient, environmentally friendly, intelligent and sustainable direction with their significant advantages in efficiency, performance, environmental protection, maintenance, space utilization, cost, safety, intelligence and compatibility. For international wholesale buyers, in-depth understanding of the advantages and market trends of electric drive shafts, selection of reliable product suppliers and partners, and active layout in this field will help you gain a favorable position in the fiercely competitive automotive parts market, seize the opportunities of the rapid development of the electric vehicle industry, achieve commercial success, and make positive contributions to the global green transportation cause.

Post time: Jun-11-2025