Preparation before heat treatment

Cleaning: Use appropriate solvents or cleaning agents to remove impurities such as oil, iron filings, dust, etc. left on the motor parts during processing to ensure surface cleanliness. This helps to evenly transfer heat during heat treatment and prevent local overheating or uneven cooling.

Inspection and repair: Carefully check the surface and interior of the motor parts for processing defects, such as cracks, sand holes, pores, etc. For defects found, repair or treat them in time to avoid the expansion of defects during heat treatment and affect the quality and performance of the parts.

Preheating: Slowly heat the motor parts to a certain temperature, usually 100℃~300℃, and the preheating time depends on the size and material of the parts. Preheating can reduce the thermal stress generated during the heat treatment process, prevent deformation or cracking of components, and improve heating efficiency to ensure the smooth progress of subsequent heat treatment steps.

Common heat treatment steps

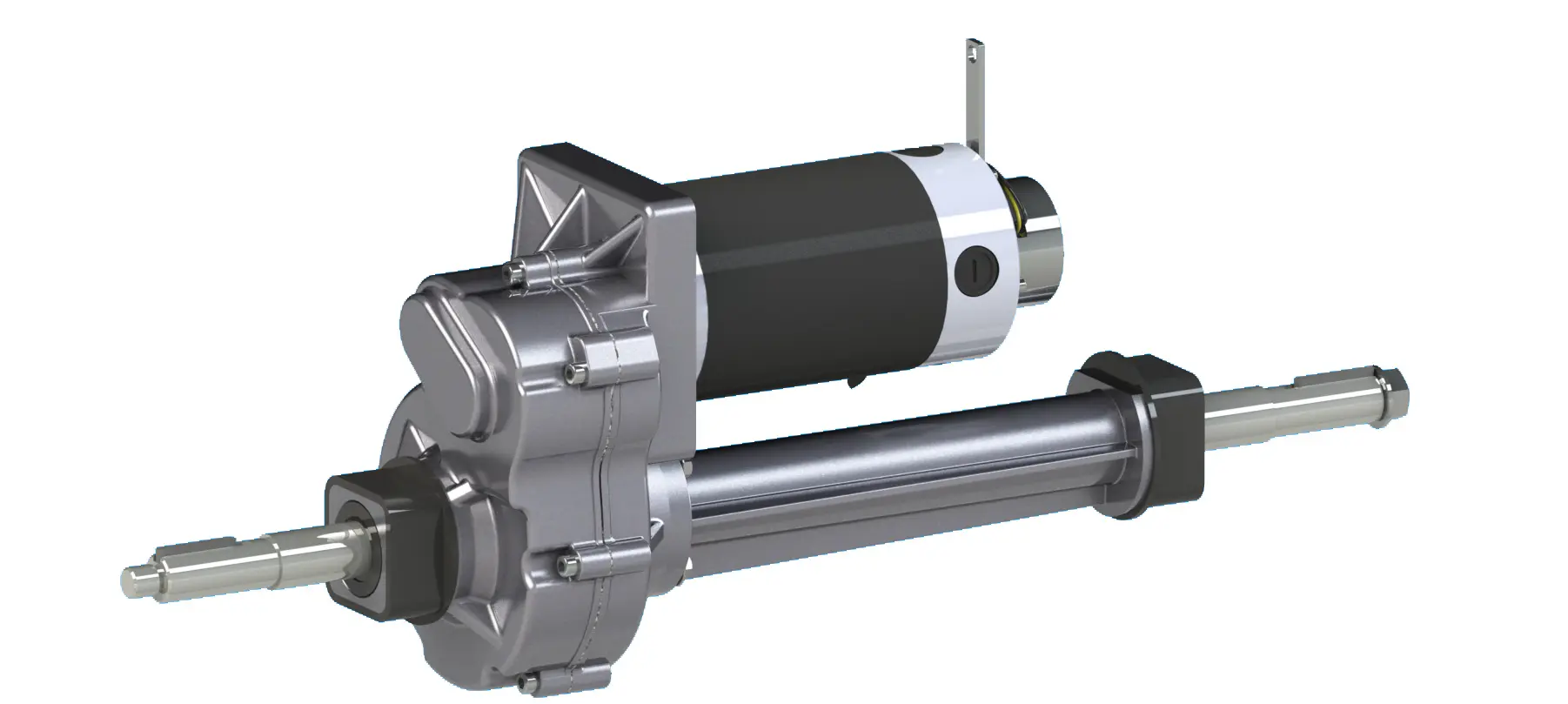

Annealing: Heat the motor components to an appropriate temperature, such as 600℃~800℃, keep them warm for a certain period of time and then slowly cool them. The cooling rate is usually controlled at 10℃/h~50℃/h. The main purpose of annealing is to reduce the hardness of the material, improve plasticity, eliminate internal stress, improve processing performance, and make the structure more uniform. This is especially important for some key components in Transaxle DC Motor, such as rotor shaft, stator core, etc., which is helpful for subsequent mechanical processing and assembly.

Normalizing: Heat the motor components to 30℃~50℃ above the critical temperature. The normalizing temperature of general carbon steel is 850℃~950℃. Keep them warm for an appropriate period of time and then cool them in the air. Normalizing can improve the strength and toughness of the material, refine the grains, improve the organizational structure, and enable the material to obtain good comprehensive mechanical properties. Compared with annealing, normalizing has a faster cooling speed and a shorter production cycle. It is suitable for the preliminary heat treatment of materials such as medium carbon steel and low carbon alloy steel, and can lay a good foundation for subsequent processing and use.

Quenching: Rapidly heat the motor parts to the quenching temperature, such as 800℃~1200℃, keep them warm for a certain period of time, and then cool them quickly. Usually, oil cooling, water cooling or brine cooling are used, and the cooling rate can reach 100℃/s~500℃/s. Quenching can significantly improve the hardness and strength of the material, forming a high-hardness quenching layer on its surface, enhancing wear resistance and fatigue resistance. However, the huge internal stress generated during the quenching process may cause deformation or cracking of the parts, so the quenching process parameters need to be strictly controlled, and tempering treatment is usually required to eliminate quenching stress.

Tempering: Heat the quenched motor parts to a temperature range below the critical temperature, such as low-temperature tempering temperature of 150℃~250℃, medium-temperature tempering temperature of 350℃~500℃, and high-temperature tempering temperature of 500℃~650℃. Keep warm for a period of time and then slowly cool. The main purpose of tempering is to reduce the brittleness of quenched steel, eliminate or reduce quenching internal stress, stabilize the organization, improve toughness, and adjust hardness and strength according to different use requirements. For example, for some motor parts that require high hardness and wear resistance, low-temperature tempering can be used; while for parts that require good comprehensive mechanical properties, high-temperature tempering can be used.

Special heat treatment process

Carburizing: Place the motor parts in a carburizing medium, and allow carbon atoms to penetrate into the surface of the parts at high temperature to form a high-carbon carburized layer. The carburizing temperature is usually 900℃~980℃, and the holding time depends on the size and requirements of the parts. After carburizing, quenching and low-temperature tempering can make the surface of the component have high hardness, high wear resistance and fatigue strength, while the core maintains good toughness and strength. It is suitable for Transaxle DC Motor parts made of low-alloy steel and other materials, such as gears, bearings, etc.

Nitriding: Place the motor component in an active nitriding medium at low temperature to allow nitrogen atoms to penetrate into the surface of the component to form a nitriding layer with high hardness, high wear resistance and high corrosion resistance. The nitriding temperature is generally 480℃~580℃, and the processing time is relatively long, usually 10h~100h. The components after nitriding have small deformation and high surface hardness, which can significantly improve the service life and reliability of motor components. They are often used in some motor parts with high precision and high performance requirements, such as shafts, gears, etc.

Induction heating surface quenching: Use the heat generated by the induction current to quickly heat the surface of the motor component to the quenching temperature, and then immediately spray water or oil to cool it to achieve surface quenching. This method has fast heating speed, high efficiency, adjustable quenching layer depth, and can accurately control the quenching area and hardness distribution. It is suitable for some parts of the Transaxle DC Motor that require high local wear resistance, such as journals, gear tooth surfaces, etc. It can effectively improve its surface hardness and wear resistance, while reducing quenching deformation.

Post-treatment after heat treatment

Cleaning and rust prevention: There may be impurities such as scale and oil on the surface of the motor parts after heat treatment, and they need to be cleaned again to ensure surface cleanliness. After cleaning, in order to prevent the parts from rusting during storage and transportation, a layer of anti-rust oil or rust inhibitor is usually applied to the surface to ensure that the quality and performance of the parts are not affected

Post time: Apr-23-2025