How to Choose Electric Transaxle Motors for Stroller or Scooter with Rear Axle

I. Core Scenario Differences Must Be Clarified Before Model Selection

The electric drive axle motor, the “heart” of the rear axle drive system, must be selected based on the specific product scenarios. The core requirements of strollers and scooters are distinct, directly determining the parameters:

1. Safety Priority for Strollers

Load Characteristics: Requires carrying an infant (approximately 15-30 kg) plus the vehicle’s weight (10-20 kg), emphasizing smooth starting and prohibiting jerking and impact.

Performance Limits: Maximum speed ≤ 5 km/h (EU EN 1888 standard), gradeability ≥ 10% (for home corridors/gentle slopes in parks).

Special Requirements: Operating noise ≤ 55 dB (to avoid disturbing infants), protection rating ≥ IP54 (to protect against spills and rainy weather).

2. Power Adaptation Logic for Scooters

Load Classification: Adult scooters (load ≤ 120 kg) vs. children’s scooters (load ≤ 50 kg), with power requirements differing by 2-3% times

Scenario differentiation: Urban commuting requires range (efficiency ≥ 85%), while off-road vehicles require torque (peak torque ≥ 35 N·m).

Compliance redline: Power ≤ 250W in the European market, ≤ 750W in the North American market. A speed limit release mechanism is required for overspeeding.

II. Calculation and Matching Guide for Key Parameters

1. Power Selection: Accurately calculate, not blindly use values.

Basic Formula: P = (Ftotal × v) / (η × 3.6) × Ks

Ftotal: Total resistance (flat road resistance + climbing resistance). Flat road resistance is μ × m × g (μ = 0.03-0.05, m = total mass). Climbing resistance is m × g × sinθ (θ is the slope angle).

η: Transmission efficiency (gear transmission 0.8-0.9, belt transmission 0.75-0.85)

Ks: Safety factor (stroller 1.5, scooter 1.6) 1.2-1.4 (Use the upper limit for slope scenarios)

Example: A 30kg stroller with a 15kg body, climbing a 15% slope at 5km/h, requires a power rating of approximately (52.32×5)/(0.85×3.6)×1.5, which is approximately 128W. A power rating of 150W or higher is recommended. 2. Torque and Speed: The Golden Ratio for Rear-Axle Drive

Torque requirement: T = P × 9550 / n (n is the motor speed). Strollers require low-speed, high torque (rated speed 200-500 rpm, peak torque ≥ 15 N·m), while scooters require a wide speed range (150-600 rpm, supporting field-weakening speed expansion).

Speed matching: Calculated based on wheel diameter, the formula v = π × D × n / (60 × i) (D = wheel diameter, i = reduction ratio). A 10-inch scooter (D = 0.254 m) equipped with a 300 rpm motor and a reduction ratio i = 5 has a speed of approximately 24 km/h, which meets regulatory requirements.

3. Voltage and Protection: Dual Guarantee of Reliability

Voltage Platform: For strollers, prioritize 12V/24V (suitable for lead-acid batteries and low cost); for scooters, choose 36V/48V (mainstream lithium batteries with high energy density). Avoid overvoltage (which can shorten battery life by over 50%).

Protection Level: IP65 (splashproof) is mandatory for outdoor use; strollers can be downgraded to IP54 (dust and splashproof). Insulation Class ≥ B (temperature resistant to 130°C).

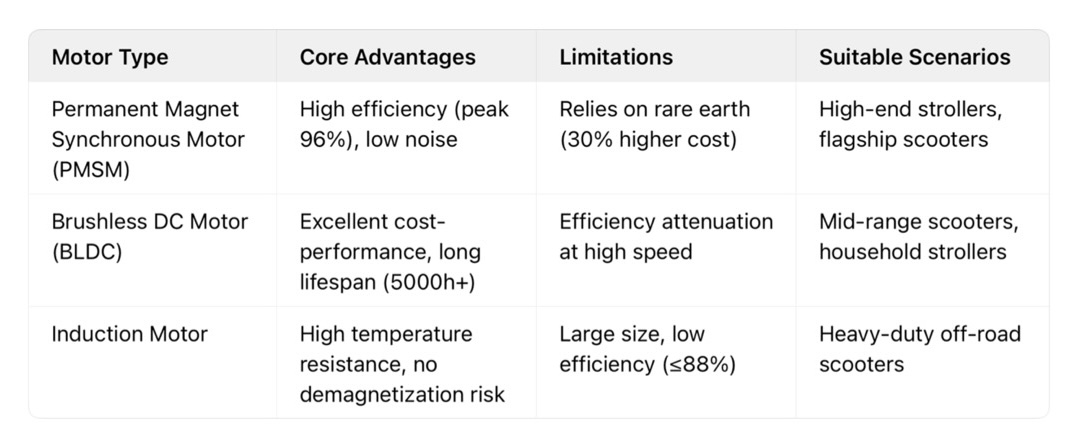

III. Motor Type Selection: Choosing the Pros and Cons of a Technical Route

Selection Recommendation: 90% of consumer-grade products prioritize BLDC/PMSM. The Anida 10″-H0050 model uses BLDC technology. Its 240-500W power range is suitable for 80% of scooter applications, and its peak torque of 35N·m can easily handle a 15° slope.

IV. International Compliance and Certification: A Passport to Entering the Target Market

1. Compulsory Certification List

EU: CE Certification (EMC EN 55014, Safety EN 60335) + RoHS Environmental Certification

North America: UL 60950 Certification (Electrical Safety) + FCC ID (Wireless Transmission, Remote Control Functions Require Additional Testing)

Global: IEC 62133 Battery Safety Certification (Motor and Battery System Integrated Testing)

2. Avoiding Certification Traps

The motor nameplate must be marked “Rated Key parameters such as “Voltage” and “Power Output” must be consistent with the certification report.

The protection level test must cover the shaft extension (the area most susceptible to water ingress), avoiding testing only the housing.

Scooters must also pass a braking performance test (electronic brake response time ≤ 0.3s).

V. Practical Selection Case Study: The Complete Process from Requirements to Implementation

Case 1: Children’s Scooter for the European Market (10-inch wheels, 50kg load)

Requirement Analysis: Speed ≤ 25km/h, Climbing 12% Grade, Range ≥ 20km

Parameter Calculation: Power ≈ (38 × 25) / (0.85 × 3.6) × 1.3 ≈ 412W, selecting a 500W BLDC motor.

Configuration: 36V voltage, peak torque 25N·m, IP65 protection, and Hall effect sensor speed control.

Certification Combination: CE+RoHS+REACH, Motor Efficiency Marked at 82% (Compliant with EU ERP Directive)

Case Study 2: Smart stroller for the North American market (8-inch wheels, 45kg load)

Requirement analysis: Speed ≤ 4 km/h, noise ≤ 50 dB, one-touch braking

Parameter calculation: Power ≈ (28 × 4) / (0.9 × 3.6) × 1.5 ≈ 51W, select a 100W PMSM motor

Configuration matching: 24V voltage, rated speed 300 rpm, soft start control, IP54 protection

Certification combination: UL + FCC + CPSC, added temperature protection (automatic power off above 100°C)

VI. Post-selection value-added services: key to improving inquiry conversion rate

Provide motor performance curves (speed-torque-efficiency 3D plot) to facilitate vehicle matching

Produce a lifespan test report (1000 hours of continuous operation without failure)

Customizable shaft extension size (adjustable from 80-130mm) and mounting flange to shorten customer R&D cycle

Post time: Oct-24-2025