How to Choose an Electric Transaxle for Stint Cargo: A Guide for Global Wholesale Buyers

As a global wholesale buyer focusing on last-mile logistics equipment, selecting the right electric transaxle for Stint Cargo—your workhorse for urban delivery, campus logistics, and short-haul freight—directly impacts operational efficiency, maintenance costs, and customer satisfaction. Unlike standard electric vehicles, Stint Cargo demands a transaxle that balances load capacity, power output, and compact design while adapting to diverse regional usage conditions. This guide breaks down the selection process into actionable, technical layers to help you make data-driven decisions.

1. Start with Stint Cargo’s Operational Requirements: Define the “Must-Haves”

Before evaluating transaxles, you must first map your Stint Cargo’s actual usage scenarios—this eliminates generic options and narrows down candidates that fit your buyers’ needs. Key parameters to clarify include:

1.1 Load Capacity: Match Rated Load to Real-World Demands

Stint Cargo typically handles 500–1,500 kg of payload (varies by model), but the electric transaxle’s capacity must account for dynamic loads (e.g., sudden acceleration, uneven roads) and safety margins.

- Rated Load vs. Peak Load: Choose a transaxle with a rated load 1.2–1.5 times your Stint Cargo’s maximum payload. For example, if your target cargo weight is 1,000 kg, a transaxle with a 1,200–1,500 kg rated load prevents overheating and component wear.

- Axle Configuration: Single-speed transaxles work for flat urban routes, while two-speed options suit hilly areas (e.g., European cities like San Francisco or Lisbon) by balancing low-speed torque for climbs and high-speed efficiency for straightaways.

1.2 Usage Environment: Adapt to Regional Conditions

Global buyers serve markets with varying climates, road types, and regulatory standards—your transaxle must withstand these variables:

- Temperature Resistance: For cold regions (e.g., Northern Europe, Canada), select transaxles with low-temperature lubricants (-30°C to 0°C) and sealed motor enclosures to prevent frost damage. For hot climates (e.g., Southeast Asia, the Middle East), prioritize heat dissipation systems (aluminum alloy housings, forced-air cooling) to avoid overheating.

- Terrain Compatibility: Rough urban roads or unpaved campus paths require transaxles with reinforced gearboxes (hardened steel gears) and shock-absorbing mounts to reduce vibration-related failures.

2. Evaluate Core Technical Specifications: Avoid “Over-Engineering” or “Under-Performance”

A transaxle’s technical parameters directly determine its compatibility with Stint Cargo. Focus on these non-negotiable metrics:

2.1 Power and Torque: Align with Speed and Climb Needs

- Motor Power: Stint Cargo for urban delivery (speeds up to 25 km/h) typically requires 3–5 kW transaxles. For heavier loads (1,200+ kg) or faster routes (30–40 km/h), opt for 5–7 kW models. Avoid over-powering—this increases energy consumption and raises costs for your buyers.

- Torque Output: Prioritize low-speed torque (200–400 N·m) for Stint Cargo, as it needs strong acceleration to navigate traffic and climb curbs. For example, a 350 N·m transaxle ensures smooth starts even with a full 1,000 kg load.

2.2 Efficiency and Energy Consumption

Wholesale buyers’ clients (logistics companies, retailers) care about battery life—so your transaxle’s efficiency directly impacts marketability:

- Transmission Efficiency: Aim for 85–95% efficiency (excluding motor losses). Hypoid gear transaxles offer higher efficiency than worm gear options for Stint Cargo, as they reduce friction and energy waste.

- Regenerative Braking Compatibility: Choose transaxles that integrate with regenerative braking systems. This feature recovers 10–15% of energy during stops, extending Stint Cargo’s range—critical for buyers in markets with long delivery routes (e.g., Australia, the U.S.).

2.3 Compact Design and Weight

Stint Cargo has limited under-chassis space, so the transaxle’s size and weight matter:

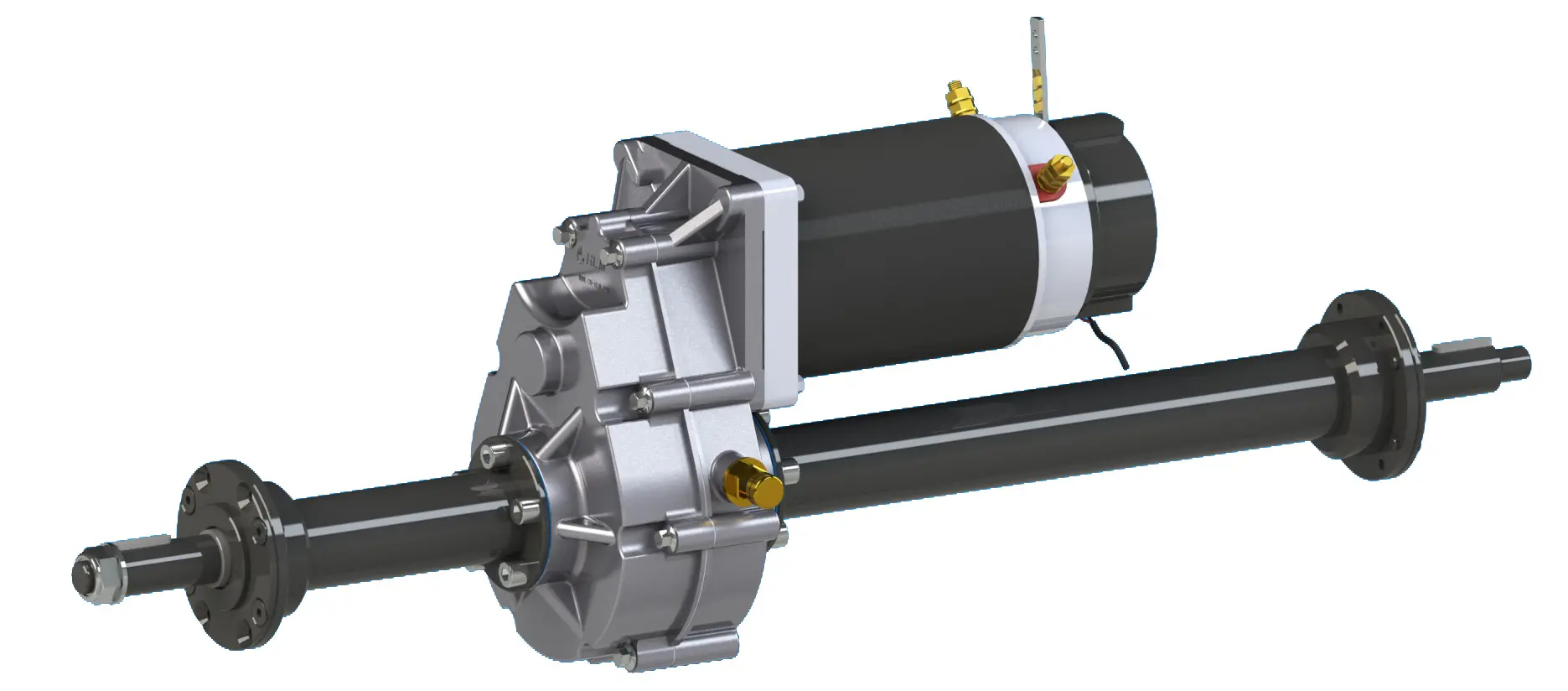

- Dimensions: Opt for integrated transaxles (combining motor, gearbox, and differential) to save space. A transaxle with a width of 400–600 mm and height under 200 mm fits most Stint Cargo chassis.

- Weight: Keep the transaxle weight under 80 kg (for 1,000 kg payload Stint Cargo). Excess weight reduces payload capacity and increases battery drain.

3. Prioritize Durability and Maintenance: Reduce Long-Term Costs

For wholesale buyers, a transaxle’s lifespan and maintenance needs directly affect your reputation—cheap, low-quality options lead to frequent returns and lost clients. Focus on these durability factors:

3.1 Material and Build Quality

- Housing: Select transaxles with die-cast aluminum alloy housings—they are lighter than steel but offer comparable strength, and resist corrosion (critical for coastal markets like Japan or Brazil).

- Gears and Bearings: Hardened alloy steel gears (e.g., 20CrMnTi) with precision grinding reduce wear; sealed ball bearings (IP67 or higher) prevent dust and water ingress, extending service life to 5,000+ operating hours.

3.2 Maintenance Accessibility

Your buyers (local distributors or logistics firms) need easy access to service components:

- Oil Change Ports: Look for transaxles with external oil fill/drain ports—this eliminates the need to disassemble the unit for routine lubrication.

- Spare Parts Availability: Partner with transaxle suppliers that offer global spare parts networks (e.g., warehouses in Europe, North America, and Asia). Delays in replacing gears or seals cost your buyers downtime—and erode trust in your products.

4. Ensure Compliance with Global Standards: Avoid Regulatory Risks

As a global buyer, non-compliant transaxles will get stuck in customs or face fines. Verify these certifications:

- Safety Standards: CE (Europe), UL/CSA (North America), and CCC (China) certifications ensure the transaxle meets electrical safety and fire resistance requirements.

- Emissions and Noise: For EU markets, the transaxle must comply with EU Directive 2000/14/EC (noise limits: ≤70 dB at 25 km/h). For California (U.S.), ensure alignment with CARB’s zero-emission vehicle (ZEV) standards.

- RoHS Compliance: Restrict hazardous substances (lead, mercury) to meet global environmental regulations—critical for buyers in eco-conscious markets like Germany or Canada.

5. Balance Cost and Value: Avoid “Race to the Bottom”

Wholesale buyers focus on margins, but choosing the cheapest transaxle often backfires. Instead, calculate total cost of ownership (TCO):

- Initial Cost: A 3–5 kW transaxle may range from

800–

1,500. Avoid units under $600—they often use low-grade materials and lack certifications.

- Maintenance Cost: A high-quality transaxle costs

50–

100/year to maintain (lubrication, seal replacements), while cheap options can cost $200+/year in repairs.

- Supplier Reliability: Partner with suppliers that offer 12–24 month warranties and technical support (e.g., online troubleshooting, on-site service for bulk orders). Suppliers with ISO 9001 certification are more likely to deliver consistent quality.

Case Study: How a European Wholesale Buyer Selected the Right Transaxle

A buyer serving European last-mile logistics firms needed a transaxle for 1,200 kg payload Stint Cargo used in hilly cities (e.g., Zurich, Vienna). Their selection process:

- Defined requirements: 1,500 kg rated load, 350 N·m torque, -20°C to 40°C temperature resistance, CE/ROHS compliance.

- Shortlisted 3 suppliers: 2 offered two-speed transaxles; 1 provided integrated regenerative braking.

- Tested samples: The winning transaxle (5 kW, 380 N·m) had 92% efficiency, IP68 sealing, and a 24-month warranty. It reduced their buyers’ maintenance costs by 30% and extended Stint Cargo’s range by 12%.

Post time: Oct-20-2025