How Long Does an Electric Transaxle Last? Key Factors, Lifespan Expectations, and Maintenance Tips

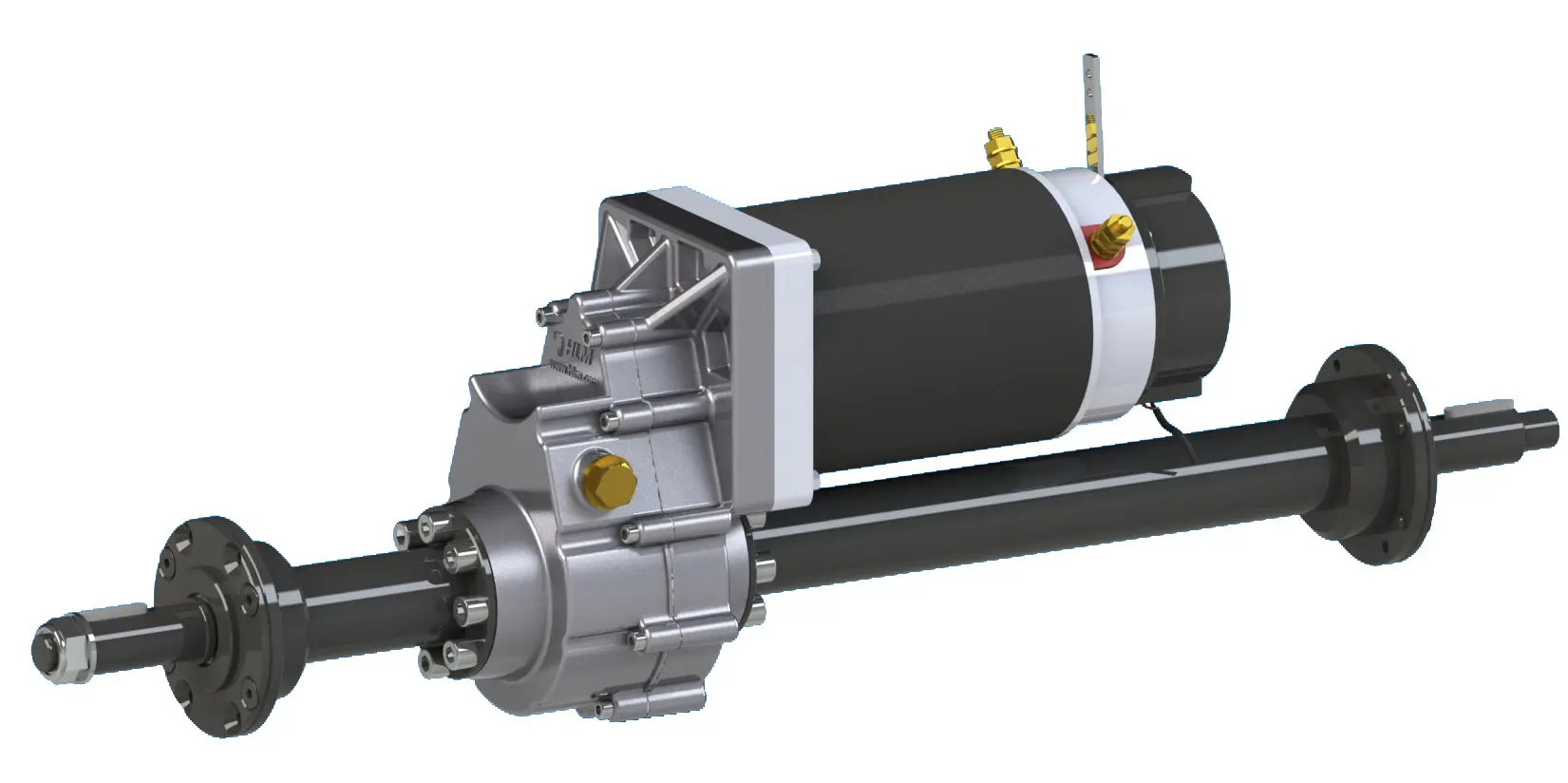

If you’re investing in electric vehicles (EVs), electric forklifts, or industrial electric machinery, one question likely looms large: How long will the electric transaxle last? As the heart of an electric vehicle’s powertrain—integrating the electric motor, gearbox, and differential into a single, compact unit—the electric transaxle’s durability directly impacts your equipment’s reliability, cost of ownership, and overall performance.

Unlike traditional internal combustion engine (ICE) transaxles, electric transaxles have fewer moving parts, simpler mechanics, and less exposure to high heat from combustion. But their lifespan isn’t set in stone. It depends on a complex interplay of design quality, usage patterns, maintenance habits, and environmental conditions. In this guide, we’ll break down everything you need to know about electric transaxle longevity—from typical lifespan ranges to actionable steps to maximize its service life.

What Is an Electric Transaxle, and Why Does Lifespan Matter?

First, let’s clarify: An electric transaxle combines three critical components into one integrated system:

Electric motor: Converts electrical energy from the battery into mechanical energy.

Gearbox (transmission): Adjusts torque and speed to match driving or operational needs.

Differential: Distributes power evenly to the wheels while allowing them to rotate at different speeds (e.g., during turns).

This integration makes electric transaxles lighter, more efficient, and easier to install than separate powertrain components. For businesses and EV owners alike, lifespan matters because:

Cost savings: A longer-lasting transaxle reduces replacement and downtime costs.

Reliability: Avoids unexpected breakdowns that disrupt operations (critical for forklifts, delivery vans, or industrial equipment).

Resale value: Well-maintained transaxles boost the resale value of EVs and machinery.

Typical Lifespan of an Electric Transaxle: What to Expect

Unlike ICE transaxles (which often last 100,000–150,000 miles with proper care), electric transaxles benefit from simpler mechanics and reduced wear. Here’s a breakdown of lifespan expectations based on application type—the biggest driver of variability:

1. Passenger Electric Vehicles (EVs)

For everyday cars, SUVs, and trucks (e.g., Tesla, Ford Mustang Mach-E, Chevrolet Bolt), electric transaxles typically last 150,000–300,000 miles (or 10–20 years) under normal use. Many EV manufacturers back this confidence with warranties:

Tesla: 8 years/120,000–150,000 miles (depending on the model).

Hyundai/Kia: 10 years/100,000 miles for the transaxle.

Nissan Leaf: 8 years/100,000 miles.

In practice, some EV owners report transaxles lasting beyond 300,000 miles with basic maintenance—thanks to fewer friction points and no need for oil changes (in most cases).

2. Commercial Electric Vehicles (Delivery Vans, Buses)

Commercial EVs face harsher conditions: frequent stop-and-go driving, heavy payloads, and longer daily mileage. Even so, their transaxles still outperform ICE equivalents, lasting 120,000–250,000 miles (5–15 years). Fleet operators often extend lifespan by adhering to strict maintenance schedules, as downtime for a delivery van or bus directly hits revenue.

3. Industrial Equipment (Forklifts, Golf Carts, Utility Vehicles)

Electric forklifts, golf carts, and warehouse utility vehicles operate in confined spaces with repeated short cycles (e.g., lifting, turning, stopping). Their transaxles are built for low-speed, high-torque use, and typically last 5,000–10,000 operating hours (or 7–12 years). For context: A forklift used 8 hours a day, 5 days a week, logs ~2,000 hours annually—meaning a well-maintained unit could serve your warehouse for a decade.

4. Off-Road Electric Vehicles (ATVs, UTVs)

Off-road electric vehicles face extreme stress: rough terrain, water, dust, and heavy loads. Their transaxles are built with rugged materials (e.g., reinforced steel housings), but lifespan drops to 3,000–8,000 operating hours (3–8 years) if not properly cleaned and maintained.

5 Key Factors That Determine Electric Transaxle Lifespan

Why do two identical electric transaxles have drastically different lifespans? The answer lies in these five variables:

1. Design and Manufacturing Quality

Not all electric transaxles are created equal. High-quality units from reputable manufacturers (e.g., BorgWarner, ZF, Aisin) use:

Premium materials: Heat-resistant alloys for gears, sealed bearings to prevent dust/water intrusion, and corrosion-resistant housings.

Precision engineering: Tighter tolerances reduce friction and wear between moving parts.

Integrated cooling systems: Liquid or air cooling prevents overheating (a top cause of premature failure).

Cheap, low-quality transaxles (often from uncertified suppliers) cut corners on materials and testing—leading to failures as early as 2–3 years.

2. Usage Patterns: “How You Use It” Matters Most

Aggressive or improper use is the #1 enemy of electric transaxle longevity. Here’s how usage impacts lifespan:

Aggressive driving: Rapid acceleration, hard braking, and frequent high-speed driving force the transaxle to work harder, increasing heat and wear on gears.

Overloading: Exceeding the transaxle’s torque or weight capacity (e.g., a forklift lifting more than its rated load) can bend gears or crack the housing.

Short trips vs. long trips: Short trips (under 10 miles) for EVs prevent the transaxle from reaching optimal operating temperature, leading to moisture buildup and rust over time.

Stop-and-go vs. highway driving: Commercial vans in city traffic experience more gear shifts and torque changes than highway EVs, accelerating wear.

3. Maintenance Habits: Simple Steps, Big Impact

Electric transaxles require less maintenance than ICE transaxles, but neglecting basic care will shorten their life. Key maintenance tasks include:

Fluid checks (if applicable): Some electric transaxles use gear oil to lubricate gears. Low or dirty oil increases friction—check levels every 15,000–30,000 miles.

Cooling system maintenance: Clean radiators or fans to prevent overheating (critical for high-use commercial vehicles).

Inspection for leaks/damage: Look for oil leaks, cracked housings, or loose connections during routine service.

Software updates: Many modern transaxles use electronic controls—updating firmware can optimize performance and reduce unnecessary stress.

4. Environmental Conditions

Extreme environments accelerate wear and corrosion:

Temperature: Extreme heat (over 100°F/38°C) degrades lubricants and weakens materials; extreme cold (below 0°F/-18°C) thickens fluids and increases friction.

Moisture and dust: Water intrusion (from puddles or washing) causes rust; dust clogs cooling systems and scratches gears.

Salt and chemicals: For EVs in snowy regions or industrial settings, road salt or chemical spills corrode metal components.

5. Battery Health

The electric motor relies on a healthy battery to deliver consistent power. A failing battery (with voltage drops or uneven power output) forces the transaxle to compensate—leading to erratic wear on gears and bearings. Maintaining your EV’s battery (e.g., avoiding full discharges, keeping it cool) indirectly extends transaxle life.

How to Extend the Life of Your Electric Transaxle: 7 Practical Tips

Want to maximize your electric transaxle’s lifespan? Follow these actionable steps:

1. Avoid Aggressive Use

For EVs: Accelerate and brake smoothly; avoid sustained high speeds (over 70 mph) when possible.

For forklifts: Don’t “jerk” the controls or lift loads beyond the rated capacity.

For off-road vehicles: Avoid deep water, mud, or rocks that could damage the transaxle housing.

2. Stick to a Maintenance Schedule

Create a calendar based on your vehicle/equipment type:

Passenger EVs: Inspect transaxle fluid (if equipped) every 30,000 miles; check cooling systems annually.

Commercial EVs: Monthly inspections for leaks and cooling system performance.

Forklifts: Daily checks for unusual noises or fluid leaks; annual deep cleaning of the transaxle.

3. Protect Against the Elements

Park EVs in garages or shaded areas to avoid extreme temperatures.

Use waterproof covers for outdoor equipment (e.g., golf carts, ATVs).

Wash undercarriages of EVs regularly in snowy regions to remove salt.

4. Maintain Battery Health

Charge EV batteries between 20–80% (avoid full charges/discharges).

Keep batteries cool (use battery thermal management systems if available).

Replace old or failing batteries promptly—don’t let a weak battery stress the transaxle.

5. Address Issues Early

Don’t ignore warning signs of transaxle trouble:

Unusual noises (grinding, whirring, or clunking).

Vibrations during acceleration or turning.

Fluid leaks under the vehicle.

Reduced performance (slower acceleration, difficulty climbing hills).

Early repairs (e.g., replacing a worn bearing) cost far less than replacing the entire transaxle.

6. Use OEM or High-Quality Replacement Parts

If you need repairs, avoid cheap aftermarket parts. OEM (original equipment manufacturer) parts or certified alternatives are designed to match your transaxle’s specifications—ensuring a proper fit and minimal wear.

7. Train Operators (for Commercial/Industrial Use)

For fleets or warehouses, train employees to use equipment properly:

Teach forklift operators to avoid overloading and harsh maneuvers.

Train delivery drivers to use smooth acceleration/braking.

Create a “reporting system” for unusual noises or performance issues.

When to Replace an Electric Transaxle

Even with perfect care, electric transaxles will eventually wear out. Here’s when to consider replacement:

Cost of repairs exceeds 50% of a new transaxle: If a gearbox rebuild or motor replacement costs half as much as a new unit, replacement is more cost-effective.

Frequent breakdowns: If the transaxle fails repeatedly (even after repairs), it’s a sign of irreversible wear.

Safety risks: A damaged transaxle (e.g., cracked housing, seized gears) can cause accidents—don’t take chances.

Obsolete technology: Older transaxles may lack efficiency or compatibility with updated batteries/controls; replacing them can improve performance and reduce energy costs.

Final Thoughts: Invest in Quality, Maintain Consistently

The lifespan of an electric transaxle boils down to two simple principles: buy quality, and maintain it well. A high-quality transaxle from a trusted manufacturer, paired with responsible use and regular maintenance, will deliver decades of reliable service—whether you’re driving a passenger EV, operating a forklift, or managing a commercial fleet.

If you’re shopping for an electric transaxle, prioritize units with strong warranties, positive customer reviews, and certifications (e.g., ISO 9001 for manufacturing quality). And remember: Small, consistent efforts—like checking fluid levels or avoiding aggressive driving—will pay off in a longer-lasting, more efficient powertrain.

Post time: Sep-05-2025