How do electric transaxles compare to traditional ones in terms of energy savings?

In the rapidly evolving world of automotive technology, electric transaxles are emerging as a game-changing component in the shift towards sustainable transportation. As the demand for energy-efficient vehicles continues to grow, it’s essential to understand how electric transaxles compare to traditional ones in terms of energy savings. This blog post will delve into the intricacies of both systems and provide a comprehensive comparison.

Efficiency of energy conversion

Traditional transaxles, which are typically found in internal combustion engine (ICE) vehicles, rely on a multi-step process to convert fuel into motion. The combustion of gasoline or diesel in the engine produces energy, which is then transmitted through various components of the drivetrain, including the transmission and differential, to ultimately power the wheels. However, this process is relatively inefficient, with a significant portion of energy lost as heat. In fact, ICEs usually only convert about 20-30% of the energy in gasoline into useful power.

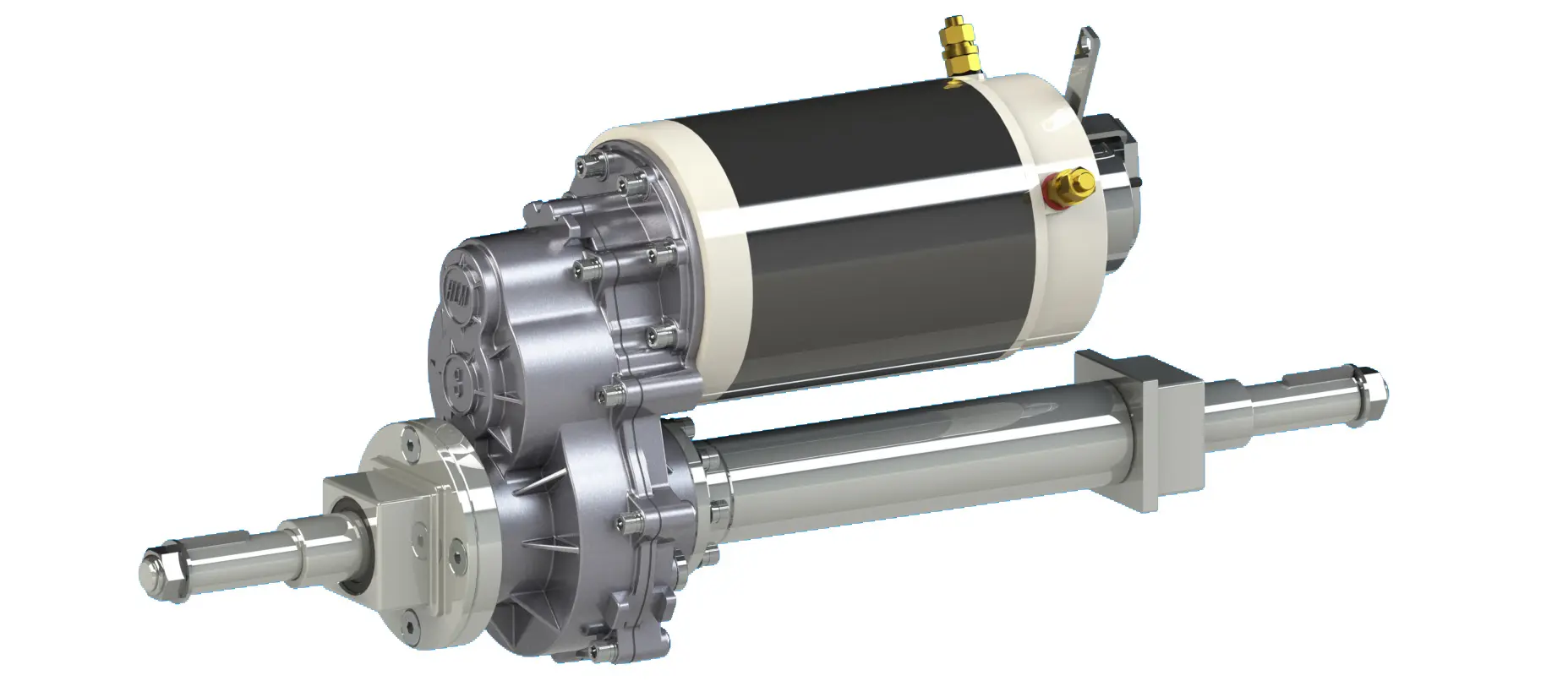

In stark contrast, electric transaxles operate on a fundamentally different principle. They integrate the electric motor, transmission, and differential into a single, compact unit. This streamlined design allows for direct energy transfer from the electric motor to the wheels, minimizing energy loss. Electric motors are highly efficient at converting electrical energy into mechanical energy, often achieving efficiencies of 85-90% or even higher. Some advanced electric transaxles can reach energy utilization efficiencies of above 90%, compared to around 70-75% for traditional ICE transaxles. This means that a greater proportion of the energy stored in the vehicle’s battery is actually used to propel the vehicle forward, resulting in significant energy savings.

Regenerative braking

One of the standout features of electric transaxles is their ability to harness energy that would otherwise be wasted. Regenerative braking is a technology employed in electric vehicles that captures the kinetic energy generated during deceleration and braking, converts it back into electrical energy, and stores it in the vehicle’s battery. When the vehicle slows down or comes to a stop, the electric motor effectively acts as a generator, reversing the usual energy flow. This recovered energy can then be reused to power the vehicle, thereby extending its driving range.

In traditional ICE vehicles, the energy generated during braking is simply dissipated as heat through the braking system and cannot be recuperated. This represents a significant loss of energy that cannot be recovered. With regenerative braking, electric transaxles can recover a portion of this energy, typically ranging from 10% to 30% of the total energy used, with some estimates suggesting that up to 70% of the energy that would otherwise be lost can be recovered. This not only improves the overall energy efficiency of the vehicle but also reduces the frequency of battery charging stops, making electric vehicles more practical and convenient for everyday use.

Optimized power management

Electric transaxles are equipped with advanced control algorithms that enable them to dynamically adapt to different driving conditions. They can adjust torque distribution in real-time based on factors such as speed, acceleration, and road conditions. This adaptive control ensures that power is used optimally, with minimal energy waste. For example, during acceleration, the electric transaxle can deliver the required torque instantaneously and efficiently, without the energy losses associated with the multiple gear shifts and complex mechanical linkages found in traditional transaxles.

Moreover, electric transaxles can work in tandem with other energy-saving systems in the vehicle, such as advanced driver assistance systems (ADAS) and vehicle-to-grid (V2G) technology. ADAS can provide real-time feedback to the driver on driving behavior and energy consumption, helping to optimize energy usage further. V2G technology allows electric vehicles to feed excess energy back into the grid, effectively turning them into mobile energy storage units. This bidirectional energy flow can help balance the grid and improve the overall energy efficiency of the transportation system.

Reduced mechanical losses

The simplified design of electric transaxles contributes to lower mechanical losses compared to traditional transaxles. Traditional transaxles consist of numerous moving parts, such as gears, clutches, and shafts, which are subject to friction and wear. These mechanical components require regular lubrication and maintenance to ensure smooth operation, and even with proper maintenance, energy is still lost due to friction and other mechanical inefficiencies.

Electric transaxles, on the other hand, have fewer moving parts and a more straightforward mechanical structure. The integration of the electric motor and transmission eliminates the need for a complex gearbox and reduces the number of components that can potentially fail or cause energy losses. The absence of clutch engagements and gear shifts, which are common in traditional transaxles and can lead to momentary disruptions in power flow and energy losses, further enhances the efficiency of electric transaxles. This results in a more reliable and energy-efficient drivetrain system.

Impact on vehicle design and weight

The compact size and lightweight nature of electric transaxles offer additional energy-saving benefits. Their integrated design allows for more efficient packaging within the vehicle, freeing up space that can be used for other purposes, such as installing a larger battery pack or optimizing the vehicle’s interior layout. A lighter vehicle requires less energy to accelerate and maintain speed, which directly translates to improved energy efficiency.

In comparison, traditional transaxles tend to be bulkier and heavier due to their complex assembly of mechanical components. The additional weight can negatively impact the vehicle’s performance and fuel economy. By reducing the weight of the drivetrain through the use of electric transaxles, manufacturers can design vehicles that are not only more energy-efficient but also more agile and responsive in terms of handling and maneuverability.

Environmental benefits

The energy savings achieved by electric transaxles have significant positive implications for the environment. As electric vehicles produce zero tailpipe emissions, the reduced energy consumption associated with electric transaxles translates to lower greenhouse gas emissions over the vehicle’s lifecycle. This is particularly important in the context of climate change and the global efforts to reduce carbon emissions.

Furthermore, the improved energy efficiency of electric transaxles means that electric vehicles can travel farther on a single charge, reducing the demand for electricity generation and the associated environmental impacts. When powered by renewable energy sources, such as solar or wind power, electric vehicles with electric transaxles can operate with an extremely low carbon footprint, helping to create a more sustainable transportation ecosystem.

Cost-effectiveness over time

While electric transaxles may have a higher initial cost compared to traditional transaxles, their superior energy efficiency leads to long-term cost savings for vehicle owners. The reduced energy consumption results in lower operating costs, as electricity is generally cheaper than gasoline or diesel on a per-mile basis. Additionally, the regenerative braking system in electric transaxles reduces wear and tear on the braking components, decreasing the frequency of brake maintenance and replacements.

The simplified mechanical structure of electric transaxles also means fewer maintenance requirements. Unlike traditional transaxles, which require regular oil changes, transmission fluid replacements, and other maintenance tasks related to their complex mechanical systems, electric transaxles have fewer parts that can wear out or require servicing. This translates to lower maintenance costs over the vehicle’s lifespan, offsetting the higher upfront cost of the electric transaxle and making electric vehicles more cost-effective in the long run.

Future developments and potential for further energy savings

As automotive technology continues to advance, electric transaxles are poised to become even more efficient and energy-saving. Ongoing research and development efforts are focused on improving the performance of electric motors, enhancing battery technology, and optimizing the overall design and integration of electric drivetrain systems. For instance, the use of lightweight materials and advanced manufacturing techniques can further reduce the weight of electric transaxles, improving energy efficiency even more.

Additionally, the integration of artificial intelligence (AI) and machine learning algorithms into electric transaxle control systems holds great promise for optimizing energy management and vehicle performance. These technologies can enable more precise control of power delivery, better prediction of driving patterns, and more efficient use of regenerative braking, all of which can contribute to further energy savings. The continuous evolution of electric transaxle technology will likely make electric vehicles an increasingly attractive and viable option for consumers and fleets looking to reduce their energy consumption and environmental impact.

Conclusion

In conclusion, electric transaxles offer substantial energy savings compared to traditional transaxles, thanks to their higher efficiency in energy conversion, regenerative braking capabilities, optimized power management, reduced mechanical losses, and positive impact on vehicle design and weight. These advantages not only translate to direct cost savings for vehicle owners but also contribute to a cleaner and more sustainable environment. As the technology continues to advance and become more widespread, electric transaxles will play a crucial role in shaping the future of transportation and driving the transition towards a low-carbon economy. For international wholesale buyers, recognizing the energy-saving benefits of electric transaxles can help identify promising market trends and opportunities in the evolving automotive landscape.

Post time: Jun-23-2025