How Do Electric Transaxles Compare to Traditional Drivetrains in Terms of Maintenance Costs?

Introduction

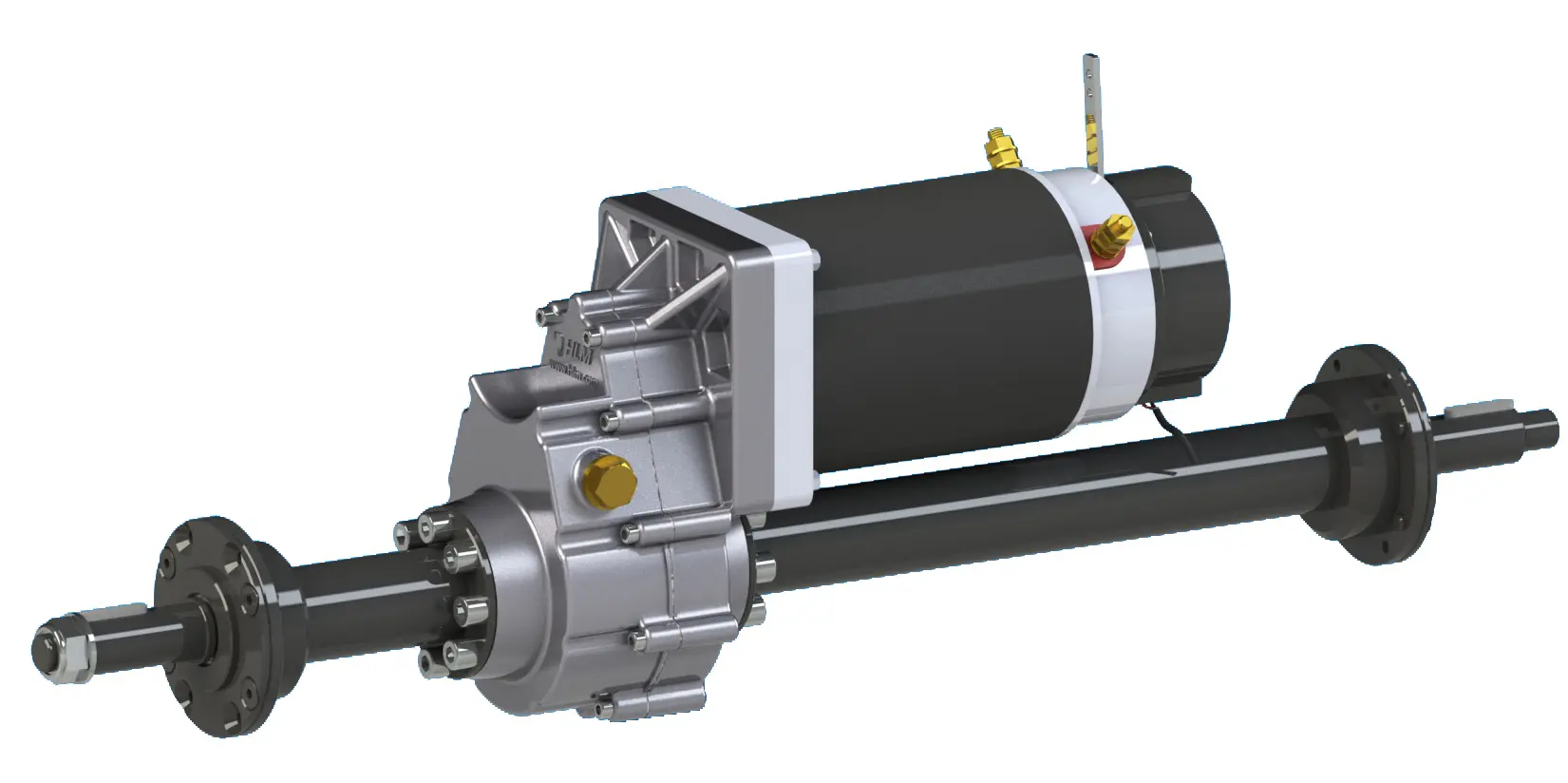

In the rapidly evolving automotive industry, the shift from traditional internal combustion engine (ICE) vehicles to electric vehicles (EVs) is gaining momentum. Central to this transition is the electric transaxle, an innovative component that integrates the electric motor, transmission, and differential into a single assembly. This blog post will delve into a comprehensive comparison of electric transaxles and traditional drivetrains, focusing on maintenance costs. By examining the differences in mechanical complexity, wear and tear, and long-term expenses, we aim to provide valuable insights for international wholesale procurement professionals who are considering the shift to electric drivetrain systems.

Mechanical Complexity and Routine Maintenance

Traditional Drivetrains

Traditional ICE vehicles rely on complex mechanical systems that include hundreds of moving parts such as pistons, camshafts, timing belts, fuel injectors, and exhaust systems. These components require regular maintenance, including oil changes, timing belt replacements, spark plug changes, and exhaust system repairs. The complexity of these systems increases the frequency and cost of maintenance visits.

Electric Transaxles

Electric transaxles, on the other hand, have a significantly simpler design. They consist of fewer moving parts, primarily the electric motor and the integrated transmission. This simplicity translates to reduced maintenance requirements. For instance, electric vehicles (EVs) do not require oil changes, timing belt replacements, or exhaust system maintenance. The fewer moving parts also mean fewer opportunities for mechanical failure.

Wear and Tear Components

Tires

Both EVs and ICE vehicles require regular tire maintenance, including rotations and alignments. However, EVs are typically heavier due to their battery packs, which can cause tires to wear out faster. Despite this, the overall maintenance cost for tires remains comparable between the two types of vehicles.

Brakes

One of the most significant differences in maintenance costs lies in brake systems. Traditional ICE vehicles rely on friction brakes, which wear down quickly and require frequent pad and rotor replacements. In contrast, EVs utilize regenerative braking, which reduces wear on brake pads and rotors. This technology can extend the lifespan of brake components significantly, resulting in lower maintenance costs.

Long-Term Maintenance Costs

Scheduled Maintenance

The Department of Energy estimates that the scheduled maintenance cost for a light-duty battery-electric vehicle (BEV) totals 6.1 cents per mile, compared to 10.1 cents per mile for a conventional ICE vehicle. This difference is primarily due to the absence of engine oil, timing belts, oxygen sensors, spark plugs, and other components found in ICE vehicles.

Unscheduled Maintenance

While EVs have fewer components that can fail, the cost of repairing high-voltage systems or replacing a battery pack can be substantial. However, these repairs are rare, especially with advancements in battery technology and extended warranties. In contrast, ICE vehicles are more prone to frequent repairs due to the higher number of moving parts and the complexity of their systems.

Total Cost of Ownership

Initial Investment

The initial cost of an electric vehicle with an electric transaxle is generally higher than that of a comparable ICE vehicle. This is primarily due to the cost of the high-voltage battery and advanced electric drivetrain components.

Long-Term Savings

Despite the higher upfront cost, the total cost of ownership (TCO) for EVs tends to be lower over time. Lower fuel expenses and reduced maintenance requirements contribute to significant cost savings. For example, a study by the International Council on Clean Transportation found that the TCO for electric vehicles could be 20% lower than comparable gasoline vehicles over a five-year period.

Environmental and Operational Benefits

Lower Emissions

Electric transaxles contribute to reduced environmental impact by eliminating tailpipe emissions. This is particularly significant in urban areas where air quality is a major concern.

Noise Reduction

Electric vehicles equipped with electric transaxles are significantly quieter than their ICE counterparts. This reduction in noise pollution enhances the quality of life in populated areas and contributes to a more pleasant driving experience.

Case Studies and Real-World Examples

Tesla Model S

The Tesla Model S is a prime example of an EV that utilizes an advanced electric transaxle system. It offers superior performance and efficiency, with lower maintenance costs compared to traditional luxury sedans. Tesla’s regenerative braking system extends brake life, and the simplified drivetrain reduces the need for frequent repairs.

Toyota Prius

The Toyota Prius has garnered acclaim for its electric transaxle system, which contributes to its impressive fuel economy and reduced maintenance requirements. The Prius demonstrates that electric transaxles can be highly reliable and cost-effective in real-world applications.

Future Trends and Innovations

Autonomous Vehicles

Electric transaxles are essential components in the development of autonomous vehicles. Their precise control and efficiency are crucial for the performance and safety of self-driving systems. Companies like Waymo and Uber are already deploying fleets of autonomous vehicles equipped with advanced electric transaxles.

Integration with Renewable Energy

As the world moves towards renewable energy sources, electric transaxles will play a pivotal role in reducing the carbon footprint of transportation. When charged with renewable energy, electric vehicles can achieve near-zero emissions.

New Business Models

The shift to electric transaxles is also driving new business models and opportunities. Companies specializing in charging infrastructure, such as ChargePoint and Electrify America, are rapidly expanding, creating jobs and contributing to a more sustainable economic ecosystem.

Conclusion

Electric transaxles represent a significant leap forward in automotive technology, offering numerous advantages over traditional drivetrains. Their enhanced efficiency, improved performance, reduced maintenance needs, and environmental benefits make them a compelling choice for modern vehicles. While the initial investment for an electric vehicle may be higher, the long-term savings in maintenance and fuel costs make electric transaxles an attractive option for international wholesale procurement professionals. As technology continues to advance, electric transaxles will play an increasingly important role in shaping the future of transportation.

electric transaxles vs traditional drivetrains maintenance

The Impact of Electric Transaxles on Long-Term Maintenance Costs

Electric transaxles, which integrate the electric motor, transmission, and differential into a single unit, have a significant impact on long-term maintenance costs compared to traditional drivetrains. Here’s a detailed analysis of how electric transaxles compare to conventional systems in terms of maintenance costs:

1. Fewer Moving Parts and Reduced Wear and Tear

Electric transaxles have a simpler design with fewer moving parts compared to traditional mechanical drivetrains. This reduction in complexity leads to decreased wear and tear, resulting in lower maintenance costs. For example, the absence of a traditional transmission can save owners an average of $200 annually in maintenance costs. Additionally, electric transaxles do not require regular oil changes, timing belt replacements, or spark plug changes, which are common maintenance tasks for internal combustion engines.

2. Longer Lifespan

The simplified structure of electric transaxles contributes to a longer lifespan compared to their mechanical counterparts. With fewer parts to fail, the average lifespan of an electric transaxle can exceed 150,000 miles. This durability not only reduces long-term costs but also enhances vehicle reliability.

3. Regenerative Braking and Reduced Brake Wear

Electric vehicles equipped with electric transaxles utilize regenerative braking, which reduces the workload on the traditional braking system. This can extend the life of the brakes and reduce the frequency of brake replacements. As a result, brake maintenance costs are significantly lower compared to traditional vehicles.

4. Lower Total Cost of Ownership

While the initial investment for an electric vehicle may be higher, the total cost of ownership tends to favor EVs over time. Lower fuel expenses and reduced maintenance requirements contribute to significant cost savings over the vehicle’s lifespan. For example, a study by the International Council on Clean Transportation found that the total cost of ownership for electric vehicles could be 20% lower than comparable gasoline vehicles over a five-year period.

5. Specialized Repairs and Component Costs

Although electric transaxles require less maintenance, repairs can be more costly when issues do occur. This is due to the specialized knowledge required and the cost of components. For instance, replacing an electric motor or battery can be expensive. However, these repairs are rare, and advancements in technology are gradually reducing the cost of components.

6. Regular Inspections and Software Updates

Proper maintenance of electric transaxles involves regular inspections and software updates. Checking the system every 10,000 miles can help identify potential issues early on. Keeping the system’s software updated ensures smooth operation and can prevent potential electronic glitches. These proactive measures can lead to cost savings by addressing minor issues before they become more extensive and expensive repairs.

7. Energy Efficiency and Operational Costs

Electric transaxles contribute to the overall energy efficiency of electric vehicles, resulting in lower operational costs. High-efficiency motors can output more power at the same energy consumption, thereby reducing operating costs. Additionally, high-efficiency motors can reduce the need for heat dissipation, lowering the energy consumption and cost of the cooling system.

Conclusion

Electric transaxles offer significant long-term maintenance cost savings due to their simplified design, reduced wear and tear, and lower operational costs. While the initial investment and potential repair costs may be higher, the overall total cost of ownership is generally lower compared to traditional drivetrains. As technology continues to advance, the cost of components and repairs is expected to decrease, further enhancing the economic benefits of electric transaxles.

Post time: Jul-07-2025