Introduction

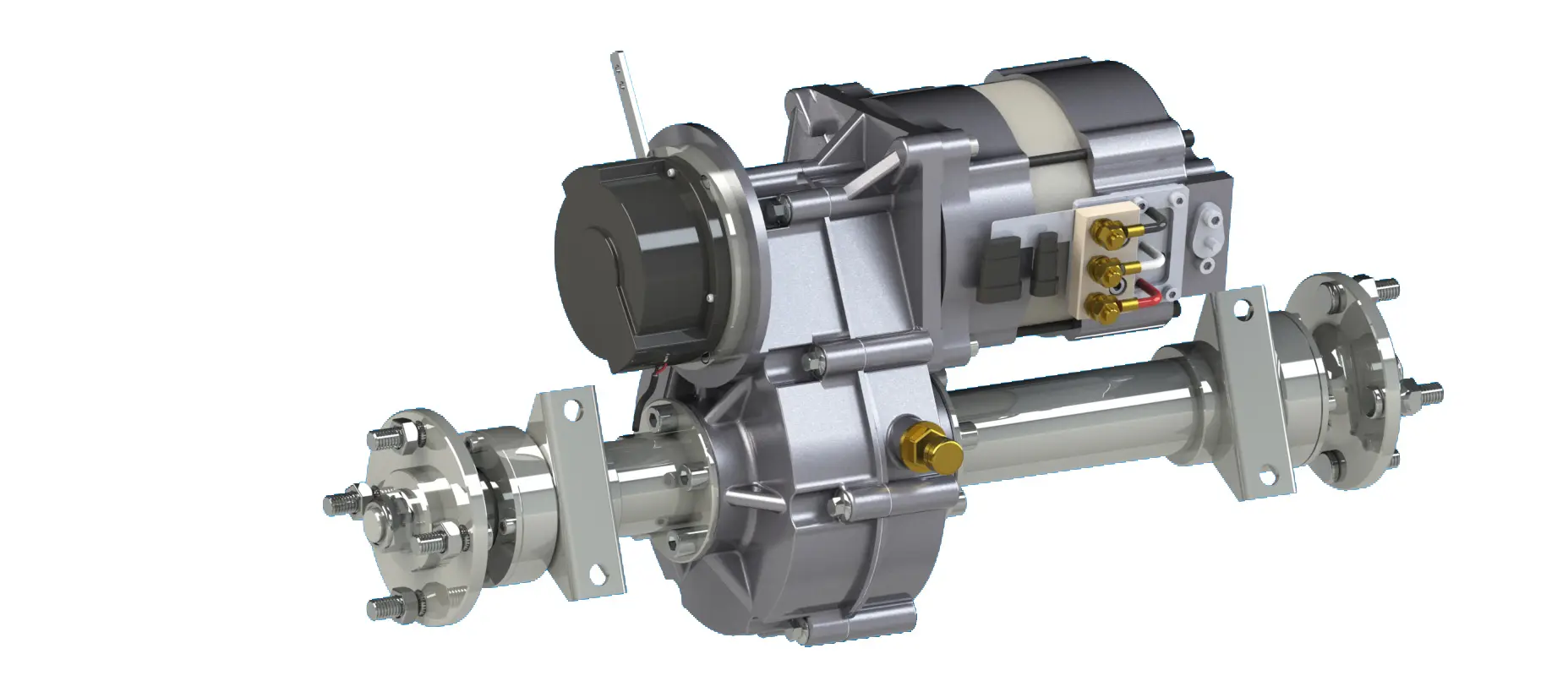

Electric transaxles are crucial components in modern electric vehicles (EVs), combining the functions of the transmission and differential into a single unit. Proper lubrication is essential for their optimal performance and longevity. When it comes to lubricants for electric transaxles, there are two main types to consider: synthetic and mineral lubricants. Understanding the differences between them can help you make an informed decision for your electric transaxle lubrication needs.

What Are Synthetic Lubricants?

Synthetic lubricants are man-made lubricants created through chemical synthesis processes. They are engineered from pure chemicals and have a uniform molecular structure. This allows for the production of lubricants with specific and tailored properties. Some common types of synthetic base oils used in lubricants include polyalphaolefins (PAOs), esters, and synthetic esters.

What Are Mineral Lubricants?

Mineral lubricants, also known as petroleum-based or conventional lubricants, are derived from crude oil through refining processes. They consist of a complex mixture of naturally occurring hydrocarbons and molecules. Despite advancements in refining technologies, mineral oils still contain impurities that can affect their performance.

Key Differences Between Synthetic and Mineral Lubricants

Production Process

Synthetic lubricants are produced through chemical synthesis, starting from basic chemical building blocks. This enables precise control over the molecular structure and properties of the lubricant.

Mineral lubricants are obtained via the distillation and refining of petroleum. The refining process helps remove some impurities, but some contaminants may still remain.

Viscosity and Viscosity Index

Synthetic lubricants generally have a higher viscosity index than mineral lubricants. This means they can maintain their viscosity more effectively across a wider temperature range, providing consistent lubrication in both low and high-temperature conditions.

Mineral lubricants may become thicker in cold temperatures and thinner in high temperatures, which can lead to increased wear on components, especially in demanding operating conditions.

Thermal Stability

Synthetic lubricants exhibit superior thermal stability. They can withstand higher operating temperatures without breaking down or oxidizing, ensuring prolonged lubricant life and enhanced performance under extreme conditions.

Mineral lubricants may start to break down at high temperatures, resulting in the formation of sludge, varnish, and deposits in the lubrication system. This breakdown can reduce lubrication effectiveness and potentially damage components.

Oxidation Resistance

Synthetic base oils have better resistance to oxidation. Their tailored molecular structure makes them less prone to reacting with oxygen, reducing the formation of harmful deposits and extending the lubricant’s service life.

Mineral oils contain impurities that can act as catalysts for oxidation. As a result, they may oxidize more quickly, especially at high temperatures, leading to a shorter service life and the need for more frequent oil changes.

Shear Stability

Synthetic lubricants offer higher shear stability, meaning they can maintain their viscosity and lubricating properties even under high shear forces. This is particularly important in applications where components are subjected to high pressures and mechanical stress.

Mineral lubricants may experience viscosity loss and reduced lubrication efficiency under similar high-shear conditions.

Low-Temperature Performance

Synthetic lubricants, especially certain types like PAO, provide superior low-temperature fluidity. This allows for easier starting and better lubrication during cold starts, ensuring that the electric transaxle is properly protected from the moment it begins operating.

Mineral lubricants can become more viscous at low temperatures, making it harder for the electric transaxle to start and potentially leading to inadequate lubrication during initial operation.

Material Compatibility

Synthetic lubricants are often formulated to be compatible with a wide range of materials, including plastics and elastomers that are commonly used in modern electric transaxles. This helps prevent swelling, shrinking, or degradation of these materials.

Some mineral lubricants may not be as compatible with certain materials, potentially causing issues with seals, gaskets, and other components made from plastics or elastomers.

Additives

Both synthetic and mineral lubricants can have additives incorporated into their formulations to enhance their performance. However, synthetic lubricants typically provide a better foundation for additives to work effectively. The pure and uniform base oils allow additives to function optimally, maximizing the benefits they provide, such as anti-wear protection, corrosion inhibition, and foam suppression.

Mineral lubricants can also benefit from additives, but their inherent impurities may sometimes interfere with the effectiveness of certain additives. This can limit the overall performance improvements that can be achieved through additive packages.

Cost

Synthetic lubricants are generally more expensive than mineral lubricants due to their complex manufacturing processes and superior performance characteristics. However, their longer service life and better protection of components can result in cost savings over time by reducing the frequency of oil changes and minimizing wear-related repairs.

Mineral lubricants are typically more cost-effective upfront, making them a more budget-friendly option for some applications where the performance requirements are not as demanding.

Environmental Impact

Synthetic lubricants have an environmental advantage in that they can be recycled and reused. Their longer service life also means fewer oil changes and less waste generated over time.

Mineral lubricants are derived from crude oil, a non-renewable resource. The extraction and refining processes of mineral oil can have negative environmental impacts, including air and water pollution.

Advantages of Synthetic Lubricants for Electric Transaxles

Enhanced Performance: The superior thermal stability, oxidation resistance, and viscosity characteristics of synthetic lubricants help electric transaxles operate more efficiently and effectively, even under extreme conditions. This can lead to improved vehicle performance and responsiveness.

Extended Service Life: Synthetic lubricants’ longer service life reduces the need for frequent oil changes. This not only saves time and maintenance costs but also minimizes downtime for electric vehicles, which is particularly beneficial for fleet operators and commercial applications.

Better Protection: The excellent lubricating properties of synthetic lubricants provide superior wear protection for the gears, bearings, and other components in electric transaxles. This helps prevent premature component failure and ensures the transaxle operates smoothly and reliably over its intended lifespan.

Improved Fuel Efficiency: By reducing friction and drag within the electric transaxle, synthetic lubricants can contribute to improved energy efficiency and potentially better fuel economy for electric vehicles. This aligns with the goals of sustainable transportation and reducing environmental impact.

Compatibility with Advanced Materials: As electric transaxle designs continue to evolve and incorporate new materials, synthetic lubricants’ compatibility with a wide range of materials ensures that they can meet the requirements of these modern components without causing compatibility issues.

Advantages of Mineral Lubricants for Electric Transaxles

Cost-Effectiveness: Mineral lubricants offer a more affordable option for lubricating electric transaxles. For applications where the operating conditions are not overly demanding and frequent oil changes are acceptable, mineral lubricants can provide satisfactory performance at a lower initial cost.

Availability: Mineral lubricants have been widely used for many years and are readily available through various suppliers and distribution channels. This makes them easily accessible for many users, including those in remote or underserved areas.

Proven Track Record: Mineral lubricants have a long history of use in various automotive and industrial applications. Many electric transaxle manufacturers and operators are familiar with their performance characteristics and have established maintenance protocols based on the use of mineral lubricants.

Considerations for Choosing Between Synthetic and Mineral Lubricants

Operating Conditions: Consider the typical operating temperatures, loads, and speeds that the electric transaxle will experience. If the transaxle is subjected to extreme temperatures, heavy loads, or high speeds, synthetic lubricants may be the better choice due to their superior performance in these conditions. For more moderate operating conditions, mineral lubricants may suffice.

Performance Requirements: Assess the performance expectations for the electric transaxle. If maximizing efficiency, longevity, and performance is a priority, synthetic lubricants can help achieve these goals. However, if the performance requirements are not as stringent and cost is a more significant factor, mineral lubricants may meet the necessary standards.

Cost-Benefit Analysis: Evaluate the upfront cost of the lubricant versus the potential long-term benefits and cost savings. While synthetic lubricants have a higher initial cost, their extended service life, improved fuel efficiency, and better protection of components can result in a more favorable cost-benefit ratio over time. Conducting a thorough analysis can help determine which lubricant type offers the best value for your specific application.

Compatibility: Ensure that the lubricant is compatible with the materials used in the electric transaxle, including metals, plastics, and elastomers. Check the lubricant manufacturer’s specifications and recommendations to avoid any compatibility issues that could lead to component damage or malfunction.

Environmental Concerns: If environmental impact is a key consideration, synthetic lubricants’ recyclability and reduced waste generation may make them the more eco-friendly option. However, it’s also important to properly dispose of or recycle used mineral lubricants to minimize their environmental footprint.

Conclusion

In conclusion, both synthetic and mineral lubricants have their own advantages and disadvantages for electric transaxles. Synthetic lubricants offer superior performance, longer service life, and better protection for electric transaxles operating in demanding conditions. They are ideal for EVs that require maximum efficiency, longevity, and performance. On the other hand, mineral lubricants provide a cost-effective solution for applications with less demanding operating conditions and where frequent oil changes are acceptable.

When selecting a lubricant for your electric transaxle, it’s essential to consider factors such as operating conditions, performance requirements, cost, compatibility, and environmental impact. By understanding the differences between synthetic and mineral lubricants and evaluating these factors, you can make an informed decision that ensures optimal lubrication and performance for your electric transaxle.

Post time: Jun-04-2025