800W Electric Transaxle: The Heart of Heavy Duty Mobility Scooters

I. Introduction

In the rapidly evolving world of electric mobility, the 800W electric transaxle has emerged as a pivotal component, particularly for heavy duty mobility scooters. This powerful and efficient drivetrain solution is transforming the way these scooters are designed, manufactured, and utilized across various markets.

II. Understanding the 800W Electric Transaxle

A. Definition and Basic Components

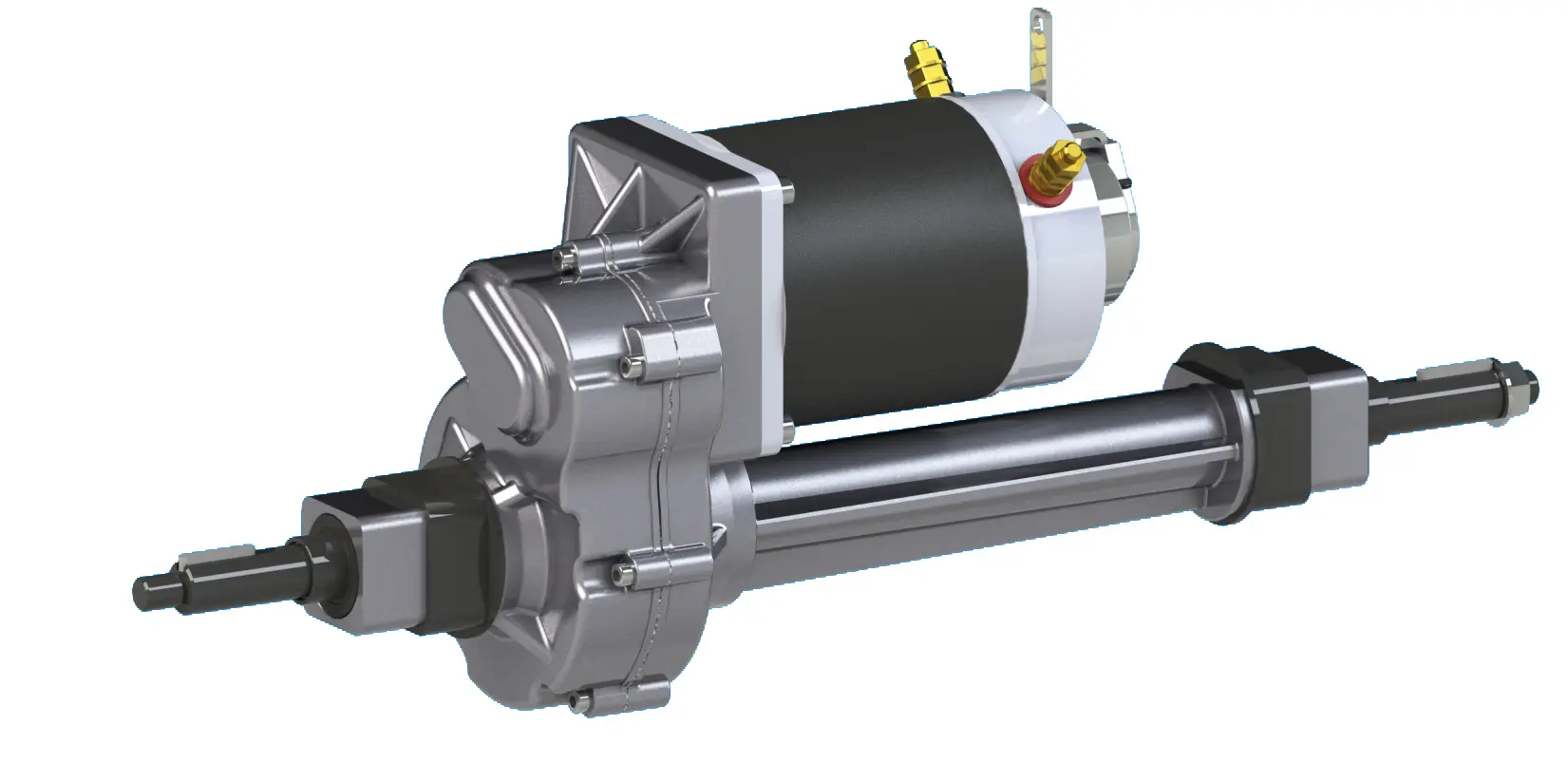

An 800W electric transaxle is an integrated assembly that combines an electric motor, gearbox, and differential in one compact unit. Its key components include:

Electric Motor: The power source, typically a brushless DC motor, which converts electrical energy into mechanical energy to drive the scooter.

Gearbox: A system of gears that transmits the motor’s power to the wheels while increasing torque and reducing speed.

Differential: Allows the wheels to rotate at different speeds, enhancing maneuverability and stability, especially during turns.

B. How It Works

When the scooter is powered on, electrical current flows to the motor, generating torque. This torque is transmitted through the gearbox, where the gears reduce the motor’s high-speed rotation to a lower, more usable speed for the wheels. The differential then distributes power to the wheels, enabling smooth and efficient movement.

III. Performance Advantages of 800W Electric Transaxles

A. High Torque Output

The 800W electric transaxle is designed to deliver significant torque, often ranging from 50 Nm to over 100 Nm. This high torque output enables heavy duty mobility scooters to effortlessly climb slopes, navigate rough terrain, and transport heavier loads without compromising performance. For instance, the 3LDM04B 800W permanent magnet brushless transaxle offers up to 50 Nm of torque, making it suitable for utility vehicles and heavy-duty scooters.

B. Enhanced Durability

Many 800W electric transaxles are built with high-quality materials such as alloy steel gears and robust housings. These materials ensure longevity and resistance to wear and tear, even under heavy usage. The LDM22-355 800W series transaxle, for example, features alloy steel hard-toothed gears and a sealed grease lubrication system, providing lasting durability and smooth steering.

C. Reduced Noise Levels

The design and engineering of 800W electric transaxles often result in quieter operation compared to traditional powertrains. Brushless motors and advanced gear designs minimize noise, making these scooters more suitable for indoor and residential environments. The LDM25-364 series transaxles operate at a noise level of ≤60dB, ensuring a peaceful and comfortable user experience.

D. Efficient Power Usage

With efficiency rates typically around 85% – 92%, these transaxles optimize power consumption, allowing for longer battery life and reduced operating costs. The 3LDM04B transaxle operates with an efficiency rate of approximately 92%, ensuring less energy wastage and longer battery life.

4. Applications in Heavy Duty Mobility Scooters

A. Personal Mobility

For individuals with mobility limitations, heavy duty mobility scooters equipped with 800W electric transaxles provide reliable and comfortable transportation. These scooters can handle longer distances and varying terrains, enabling users to maintain their independence and mobility.

B. Commercial Use

In commercial settings such as warehouses, factories, and airports, these scooters are used for material handling and transportation. The high torque and durability of the transaxles make them ideal for moving heavy loads over long distances.

C. Recreational Purposes

Heavy duty mobility scooters are also popular for recreational activities like hunting, fishing, and camping. The 800W electric transaxle’s off-road capabilities and power allow users to explore rough and uneven terrain with ease.

5. Technical Specifications and Customization Options

A. Key Specifications

Power Output: 800W

Voltage: Commonly 24V, 36V, or 48V DC

Torque: Varies by model, typically 50 – 100 Nm

Speed: Maximum speeds ranging from 20 km/h to 30 km/h

Weight: Usually between 20 kg and 40 kg

Dimensions: Compact designs to fit into scooter frames

B. Customization

Many manufacturers offer customization options to meet specific client requirements. These can include adjustments to voltage, speed, shaft length, and other parameters. For example, the LDM22-355 transaxle supports customization in voltage options, speed, shaft length, and other aspects to accommodate specific user needs.

6. Market Trends and Future Outlook

A. Growing Demand

The demand for heavy duty mobility scooters is on the rise due to an aging population, increased awareness of mobility solutions, and advancements in electric vehicle technology. As a critical component, the 800W electric transaxle market is expected to grow correspondingly.

B. Technological Innovations

Future developments may include improvements in motor efficiency, enhanced battery integration, and the adoption of smart technologies for better performance monitoring and control.

7. Conclusion

The 800W electric transaxle represents a significant advancement in the field of heavy duty mobility scooters. Its combination of high torque, durability, efficiency, and quiet operation makes it an ideal choice for a wide range of applications. As technology continues to evolve, we can expect even more innovations and improvements in these transaxles, further enhancing the mobility and independence of users worldwide.

If you’re considering purchasing or manufacturing heavy duty mobility scooters, the 800W electric transaxle is undoubtedly a key component to focus on. Its performance advantages and versatility make it a worthwhile investment for both personal and commercial use.

Post time: May-14-2025