800W Electric Drive Axle: Reinventing Transport Cart Power, Enabling Efficient Logistics and Industrial Handling

In warehousing, factory floors, e-commerce sorting, and other scenarios, transport carts (transfer vehicles/transfer vehicles) are the core tools connecting goods, locations, and lines. The drive axle, as its power center, directly determines handling efficiency, energy costs, and equipment stability. With the industry’s growing demand for lightweight, adaptable, and low-maintenance equipment, a drive axle precisely matched to light and medium-load scenarios is crucial. The 800W electric drive axle was designed for this purpose. It addresses the shortcomings of low-power drive axles (lack of power and frequent stalls) while avoiding the high energy consumption and cost of high-power options, making it an ideal choice for transport cart upgrades.

I. Why is the 800W electric drive axle the “golden power solution” for transport carts?

Transport carts often operate in complex and diverse scenarios, ranging from frequent starts and stops in warehouses to short, heavy-load operations within factories. They may also face minor slopes or dusty terrain. The 800W electric drive axle, through a balanced design of power and adaptability, precisely addresses three key pain points:

1. Power output: Just right for light and medium-duty applications, balancing efficiency and energy savings.

Power compatibility: The 800W rated power isn’t a spurious setting. Designed for 1-3 ton transport carts (mainstream light and medium-duty specifications), it provides sufficient torque (peak torque exceeding 150 Nm, depending on the model) to ensure smooth starts when fully loaded and smooth climbing (compatibility with typical factory slopes of up to 5°). This ensures that battery life isn’t compromised due to excess power (compared to a 1000W drive axle, battery life is increased by 15%-20% with the same battery capacity). Motor Efficiency: Utilizing permanent magnet synchronous motor technology, the motor boasts an efficiency exceeding 88% (far exceeding the 80% average for traditional series-wound motors). This allows for more efficient energy conversion, making it particularly suitable for the intermittent operation and frequent start-stop conditions of transport carts, reducing inefficient energy consumption.

2. Compatibility: Compatible with a wide range of cart types, reducing modification and procurement costs.

Chassis Compatibility: Customizable mounting holes and output shaft specifications allow for direct adaptation to mainstream cart structures, including flatbed carts, fence carts, and folding carts. This eliminates the need for extensive cutting or welding of the cart chassis, allowing manufacturers to quickly upgrade equipment and shorten production cycles.

Voltage Flexibility: By default, it supports 48V/60V lead-acid or lithium batteries (the mainstream power supply specifications for transport carts on the market). A 72V version can be customized for specialized scenarios, eliminating the need for additional battery pack replacement and reducing the hidden costs associated with replacing the battery pack with the axle.

3. Stability and Durability: A Reliable Backbone for Complex Operating Conditions

IP65 fully sealed design protects against warehouse dust, splashing water (such as after cleaning), and even brief rain (such as during short-distance outdoor transport). This prevents damage to the internal motor and gears due to moisture and dust accumulation, extending service life.

Transmission Structure: A built-in high-precision helical gear reduction mechanism (rather than conventional spur gears) provides smoother meshing and lower noise (operating noise ≤ 65dB, ideal for quiet workshops). Wear resistance is also improved by 30%, reducing gear wear and failure probability after long-term use.

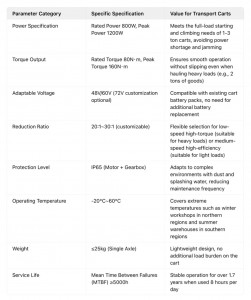

II. 800W Electric Drive Axle Core Technical Parameters: Analyzing “Hard Capabilities” from the Data

Professional buyers often focus on the “real meaning” of parameters, rather than simply numbers. The following are the core parameters and corresponding values of the 800W electric drive axle to help you quickly determine whether it is suitable for your needs:

III. Typical Application Scenarios for the 800W Electric Drive Axle: Where is it needed? From warehousing to industrial, e-commerce to manufacturing, the 800W electric drive axle, with its balanced design, has been widely used in the following scenarios, resolving practical handling pain points:

1. Warehousing and Logistics: An Efficiency Accelerator for Cargo Transfer

Requirement: Within a warehouse, transport carts frequently transfer cargo between racking areas and outbound ports (with a single trip load of 1-2 tons and a distance of 50-200 meters). They require fast start-up, low noise, and long battery life.

Product Value: The 800W drive axle has a start-stop response time of ≤0.5 seconds, eliminating process delays caused by power delays. Its low noise design does not interfere with communication between warehouse personnel. Its energy-saving features enable continuous operation for 8 hours a day (with a 100Ah lithium battery) without the need for frequent recharging.

2. Factory Workshops: A Stable Guarantee for Material Handling

Scenario Requirements: Within workshops such as automotive parts factories and electronics plants, transport carts must transport semi-finished products and tools (load capacity 1.5-3 tons). Floors may be slightly oily or sloped (such as the gentle slope of a converted workshop entrance step), requiring durability and oil resistance.

Product Value: IP65 protection and oil-resistant seals protect against oil corrosion in the workshop; high peak torque easily handles gentle slopes of 3-5° without slipping when fully loaded; wear-resistant gear design withstands 100+ starts and stops per day, reducing equipment downtime and maintenance.

3. E-commerce Sorting: A Flexible Partner for Sorting Carts

Scenario Requirements: Sorting carts (load capacity 0.8-1.5 tons) in e-commerce sorting centers need to move quickly between sorting platforms, frequently turning and starting and stopping, requiring a compact size and flexible control. Product Value: A single axle weighs ≤ 25kg and is compact (approximately 300×150×200mm in length, width, and height), taking up minimal space on the cart. It supports linkage with the steering system, ensuring smooth power output during steering and preventing cargo from falling due to bumps.

4. Short-Distance Transfers in Parks: An Adaptable Player for Outdoor Transport

Scenario Requirements: Within logistics and industrial parks, transport carts need to make short-distance transfers (200-500 meters) from warehouses to trucks, or from workshops to park gates. These transports may be exposed to rain or gravel, requiring waterproofing and impact resistance.

Product Value: The IP65 waterproof design withstands brief periods of rain. The housing is constructed of high-strength aluminum alloy, resistant to minor impacts (such as curb strikes), and the internal gearbox features a buffer structure to prevent the ingress of gravel.

IV. Installation and Maintenance: Making the 800W Drive Axle “Easy and Cost-Effective”

For manufacturers and end users, “easy installation and low maintenance” are key to reducing costs. The 800W electric drive axle was designed with these two key considerations in mind:

1. Installation: Quickly adapt in three steps, no specialized engineer required.

Step 1: Hole Matching: A universal installation drawing is provided, allowing hole positions to be adjusted to the Cart chassis dimensions (with tolerances within 10mm), eliminating the need for re-drilling.

Step 2: Wiring Adaptation: The motor cable utilizes a waterproof plug for plug-and-play connection to the Cart controller, eliminating the need for complex wiring and debugging.

Step 3: Testing and Calibration: A simple testing tool is provided. After installation, simply test the start/stop, steering, and load operation functions. Calibration can be completed in less than 10 minutes.

Note: For bulk purchases, we provide free technical guidance videos and can dispatch engineers to assist with initial installation.

2. Maintenance: Only required twice a year, costing less than 100 yuan

Daily Inspection: Only two checks are required weekly: ① Check the wiring connector for loose connections (to prevent poor contact); ② Check the gearbox oil level (visible through the oil level window, no disassembly required);

Regular Maintenance: Deep maintenance is performed every six months: ① Replace the gearbox grease (a 100ml bottle is sufficient, costing approximately 50 yuan); ② Clean the motor cooling holes (use compressed air to remove dust, no disassembly required);

Troubleshooting: A “Fault Code Manual” is provided. If problems such as motor failure or abnormal noise occur, the controller displays a code to quickly identify the cause (e.g., code E01 indicates insufficient voltage, E02 indicates insufficient gearbox oil), eliminating the need for a return to the factory.

V. User Case: How does the 800W drive axle help customers solve their pain points?

Case 1: A Warehousing Equipment Manufacturer (Jiangsu)

Pain Point: The previous 600W drive axle resulted in customer complaints about insufficient power and frequent stalling of the 1.5-ton cart when climbing slopes. After switching to a 1000W drive axle, customers complained about reduced battery life and increased battery costs.

Solution: Switching to an 800W electric drive axle paired with a 60V lithium battery.

Result: A 1.5-ton fully loaded cart can easily climb a 5° slope, and battery life has increased from 6 hours to 8 hours. Customer returns have decreased by 80%, and volume orders have increased by 30%.

Case 2: An Electronics Factory (Guangdong)

Pain Point: The workshop transport cart (with a load capacity of 2 tons) used a traditional mechanical drive, which generated high noise levels (over 80dB), impacting the workshop environment. Worn gears required monthly replacement, resulting in high maintenance costs. Solution: Replaced with an 800W electric drive axle with a silent gearbox.

Result: Operating noise reduced to 62dB, meeting workshop quietness standards; gearbox wear reduced by 30%, maintenance interval extended from one month to six months, and annual maintenance costs reduced by 7,000 yuan.

VI. Conclusion: Choosing an 800W electric drive axle means choosing “balance and reliability.”

When choosing a power source for transport carts, “too much is wasteful, too little is weak.” The 800W electric drive axle is designed to precisely match light and medium load scenarios. It addresses the power limitations of low-power models while avoiding the energy waste of high-power models, while also ensuring adaptability, stability, and ease of maintenance.

Whether it’s a warehouse equipment manufacturer looking to enhance product competitiveness or an end user looking to upgrade the power system of an existing cart, the 800W electric drive axle is a cost-effective option. It’s more than just a component; it’s a power solution that improves handling efficiency and reduces costs.

Post time: Oct-29-2025